Abstract

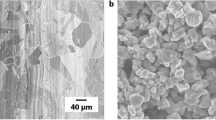

Zirconium dioxide (ZrO2)-based composites with WC addition are demonstrated to be suitable for electrical discharge machining (EDM) in deionized water. ZrO2-based composites with 40 vol. % WC, obtained from distinctive WC powder sources, were produced in order to derive correlations between material removal rate (MRR), surface finish, wire EDM parameters and material properties. Dry reciprocating sliding experiments on wire-electrical discharge machined ZrO2-WC composite samples against WC-Co cemented carbide, performed using a pin-on-plate testing rig, revealed a significant influence of the microstructure of the secondary WC-phase on wire EDM behavior and frictional characteristics.

Similar content being viewed by others

References

Hannink RHJ, Kelly PM, Muddle BC (2000) Transformation toughening in zirconia-containing ceramics. J Am Ceram Soc 83(3):461–487

Bocanegra-Bernal MH, De La Torre SD (2002) Phase transitions in zirconium dioxide and related materials for high performance engineering ceramics. J Mater Sci 37(23):4947–4971 DOI 10.1023/A:1021099308957

Smuk B, Szutkowska M, Walter J (2003) Alumina ceramics with partially stabilized zirconia for cutting tools. J Mater Process Tech 133(1–2):195–198 DOI 10.1016/S0924-0136(02)00232-7

Huang CZ, Zhang L, He L, Liu HL, Sun J, Fang B, Li ZQ, Ai X (2002) A study on the development of a composite ceramic tool ZrO2/(W, Ti)C and its cutting performance. J Mater Process Tech 129(1–3):349–353 DOI 10.1016/S0924-0136(02)00644-1

Sornakumar T, Krishnamurthy R, Gokularathnam CV (1993) Machining performance of phase transformation toughened alumina and partially stabilized zirconia composite cutting tools. J Europ Ceram Soc 12(6):455–460 DOI 10.1016/0955-2219(93)90079-7

Sergo V, Lughi V, Pezzotti G, Lucchini E, Meriani S, Muraki N, Katagiri G, Nishida T (1998) The effect of wear on the tetragonal-to-monoclinic transformation and the residual stress distribution in zirconia-toughened alumina cutting tools. Wear 214(2):264–270 DOI 10.1016/S0043-1648(97)00208-1

Myint MH, Fuh JYH, Wong YS, Lu L, Chen ZD, Choy CM (2003) Evaluation of wear mechanisms of Y-TZP and tungsten carbide punches. J Mater Process Tech 140(1–3 SPEC.):460–464

Willmann G (2002) Bioceramics in joint replacement: State-of-the-art and future options. CFI Ceram Forum Int 79(5):E27–E31

Willmann G (1997) Standardization of zirconia ceramics for total hip replacements. Biomed Tech 42(12):342–346

Burger W, Richter HG, Piconi C, Vatteroni R, Cittadini A, Boccalari M (1997) New Y-TZP powders for medical grade zirconia. J Mater Sci: Mater Med 8(2):113–118

Kosmac T, Oblak C, Jevnikar P, Funduk N, Marion L (2000) Strength and reliability of surface treated Y-TZP dental ceramics. J Biomed Materi Res 53(4):304–313

Morita Y, Nakata K, Ikeuchi K (2003) Wear properties of zirconia/alumina combination for joint prostheses. Wear 254:147–153 DOI 10.1016/S0043-1648(02)00296-X

Kim J-D, Lee Y-B, Park Se-H (1994) Study on the honing of zirconia ceramics by diamond abrasive sticks. J Mater Process Tech 41(2):201–212 DOI 10.1016/0924-0136(94)90061-2

Vleugels J, Van der Biest O (1999) Development and characterization of Y2O3-stabilized ZrO2 (Y-TZP) composites with TiB2, TiN, TiC, and TiC0.5N0.5. J Am Ceram Soc 82(10):2717–2720

Basu B, Vleugels J, Van der Biest O (2002) Toughness optimisation of ZrO2-TiB2 composites. Key Eng Mater 206–213(2):1177–1180

Salehi S, Van der Biest O, Vleugels J (2006) Electrically conductive ZrO2-TiN composites. J Europ Ceram Soc 26(15):3173–3179 DOI 10.1016/j.jeurceramsoc.2005.10.010

Jiang D, Salehi S, Vanmeensel K, Vleugels J, Van der Biest O (2005) Development and characterization of ZrO2-TiC0.5N0.5 nanocomposites. Proc 9th Conf and Exhibition Europ Ceram Soc, Slovenia, pp 19–23

Pedzich Z, Haberko K, Piekarczyk J, Faryna M, Litynska L (1998) Zirconia matrix-tungsten carbide particulate composites manufactured by hot-pressing technique. Mater Lett 36:70–75 DOI 10.1016/S0167-577X(98)00010-X

Pedzich Z, Haberko K (1997) Toughening mechanisms in the TZP- WC particulate composites. Key Eng Mater 136(3):2076–2079

Anné G, Put S, Vanmeensel K, Jiang D, Vleugels J, Van der Biest O (2005) Hard, tough and strong ZrO2-WC composites from nanosized powders. J Europ Ceram Soc 25:55–63 DOI 10.1016/j.jeurceramsoc.2004.01.015

Jiang D, Van der Biest O, Vleugels J (2007) ZrO2-WC nanocomposites with superior properties. J Europ Ceram Soc 27:1247–1251 DOI 10.1016/j.jeurceramsoc.2006.05.028

Bonny K, De Baets P, Vleugels J, Salehi A, Van der Biest O, Lauwers B, Liu W (2008) Sliding wear of electrically conductive ZrO2-WC composites against WC-Co cemented carbide. Tribol Lett DOI 10.1007/s11249-008–9326-1

Bonny K, De Baets P, Vleugels J, Salehi A, Van der Biest O, Lauwers B, Liu W (2008) Influence of secondary electro-conductive phases on the electrical discharge machinability and frictional behavior of ZrO2-based ceramic composites. J Mater Process Tech. DOI 10.1016/j.jmatprotec.2008.01.020

Lauwers B, Kruth J-P, Liu W, Eeraerts W, Schacht B, Bleys P (2004) Investigation of material removal mechanisms in EDM of composite ceramic materials. J Mater Process Tech 146(1–3):347–352 DOI 10.1016/j.jmatprotec.2004.02.013

Kozak J, Rajurkar KP, Chandarana N (2004) Machining of low electrical conductive materials by wire electrical discharge machining (WEDM). J Mater Process Tech 149/1–3:266–271 DOI 10.1016/j.jmatprotec.2003.11.055

Konig W, Dauw DF, Levy G, Panten U (1988) EDM-future steps towards the machining of ceramics. Annals of the CIRP 37(2):623–631

Tsuchiya H, Inoue T, Miyazaki M (1985) Wire electro-chemical discharge machining of glasses and ceramics. Bull Jpn Soc Precis Eng 19(1):73–74

Lok YK, Lee TC (1997) Processing of advanced ceramics using the wire-cut EDM process. J Mater Process Tech 63(1–3):839–843 DOI 10.1016/S0924-0136(96)02735-5

Sanchez JA, Cabanes I, Lopez de Lacalle LN, Lamikiz A (2001) Development of optimum electrodischarge machining technology for advanced ceramics. Int J Adv Manuf Tech 18(12):897–905 DOI 10.1007/PL00003958

Tani T, Fukuzawa Y, Mohri N, Saito N, Okada M (2004) Machining phenomena in WEDM of insulating ceramics. J Mater Process Tech 149(1–3):124–128 DOI 10.1016/j.jmatprotec.2003.12.027

Liu YH, Ji RJ, Li XP, Yu LL, Zhang HF, Li QY (2008) Effect of machining fluid on the process performance of electric discharge milling of insulating Al2O3 ceramic. Int J Mach Tools and Manuf. DOI 10.1016/j.ijmachtools.2007.12.011

Liu YH, Li XP, Ji RJ, Yu LL, Zhang HF, Li QY (2008) Effect of technological parameters on the process performance for electric discharge milling of insulating Al2O3 ceramic. J Mater Process Tech. DOI 10.1016/j.jmatprotec.2007.12.143

Matsuo T, Oshima E (1992) Investigation on the optimum carbide content and machining condition for wire EDM of zirconia ceramics. CIRP Annals Manufacturing Technology 41(1):231–234 DOI 10.1016/S0007-8506(07)61192-5

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bonny, K., De Baets, P., Vleugels, J. et al. EDM machinability and frictional behavior of ZrO2-WC composites. Int J Adv Manuf Technol 41, 1085–1093 (2009). https://doi.org/10.1007/s00170-008-1551-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-008-1551-0