Abstract

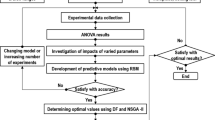

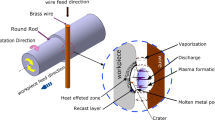

This paper presents a utility-based Taguchi loss function strategy for the multi-response optimization of electro-chemical honing (ECH) process. ECH is a precision micro-finishing technology that hybridizes electro-chemical machining and conventional honing principles to provide controlled functional work surface-generation and fast material removal capabilities in a unique single operation. The approach utilizes a composite utility function using the Taguchi loss functions of multiple ECH responses in selecting the optimal parametric settings such that the overall functional utility of the product is maximized. The use of the Taguchi loss functions ensures the process is robust against the random variations. Actual experiments confirm the feasibility of the strategy over a wide range of machining conditions employed in ECH.

Similar content being viewed by others

References

Dubey AK, Shan HS, Jain NK (2006) Analysis of surface roughness and out-of-roundness in electro-chemical honing process. Proc 1st Int and 22nd AIMTDR, IIT Roorkee (India) Dec 21–23. Int J Adv Manuf Technol, DOI 10.1007/s00170-007-1180-z

Dubey AK, Shan HS, Jain NK (2006) Precision micro-finishing by electro-chemical honing. Proc Int Conf on Manuf Sci and Technol, Melaka Aug 28-30: 173–176. Int J Manuf Technol Manage (accepted)

Dubey AK (2006) Development of the setup and performance optimization of electro-chemical honing process. PhD Thesis, IIT Roorkee, India

Ross PJ (1988) Taguchi techniques for quality engineering. McGraw-Hill Book Company, New York

Myers RH, Carter WH (1973) Response surface techniques for dual-response systems. Technometrics 15:301–307 DOI 10.2307/1266990

Derringer G, Suich R (1980) Simultaneous optimisation of several response variables. J Qual Technol 12(4):214–218

Khuri AI, Conlon M (1981) Simultaneous optimization of multiple responses represented by polynomial regression function. Technometrics 23:363–375 DOI 10.2307/1268226

Byrne DM, Taguchi S (1987) The Taguchi approach to parameter design. Qual Progr 20(12):19–26

Logothetis N, Haigh A (1988) Characterizing and optimizing multi-response processes by the Taguchi method. Qual Relia Eng Int 4(2):159–169 DOI 10.1002/qre.4680040211

Shiau GH (1990) A study of the sintering properties of iron ores using the Taguchi’s parameter design. J Chin Stat Assoc 28:253–275

Phadke MS (1989) Quality engineering using robust design. Prentice Hall, NJ

Elsayed EA, Chen A (1993) Optimal levels of process parameters for products with multiple characteristics. Int J Prod Res 31(5):1117–1132 DOI 10.1080/00207549308956778

Pignatiello JJ Jr (1993) Strategies for robust multi-response quality engineering. IIE Trans 25(3):5–15 DOI 10.1080/07408179308964286

Layne KL (1995) Methods to determine optimum factor levels for multiple responses in the designed experimentation. Qual Eng 7(4):649–656 DOI 10.1080/08982119508918813

Tong L-I, Su C-T (1997) Optimizing multi-response problems in Taguchi method by fuzzy multiple attribute decision making. Qual Relia Eng Int 13:25–34 DOI 10.1002/(SICI)1099-1638(199701)13:1<25::AID-QRE59>3.0.CO;2-B

Floros JD, Chinnan MS (1998) Computer graphics-assisted optimization for product and process development. Food Technol 42:72–78

Antony J (2000) Multi-response optimization in industrial experiments using Taguchi quality loss function and principal component analysis. Qual Relia Eng Int 16:3–8 DOI 10.1002/(SICI)1099-1638(200001/02)16:1<3::AID-QRE276>3.0.CO;2-W

Cook DF, Ragsdale CT, Major RL (2000) Combining a neural network with a genetic algorithm for process parameter optimization. Eng Appl Artif Intell 13:391–396 DOI 10.1016/S0952-1976(00)00021-X

Wang K, Gelgele HL, Wang Y, Yuan Q, Fang M (2003) A hybrid intelligent method for modeling the EDM process. Int J Mach Tools Manuf 43:995–999 DOI 10.1016/S0890-6955(03)00102-0

Srinivasu DS, Ramesh Babu N, Srinivasa YG (2004) Neuro-genetic approach for automatic selection of process parameters in abrasive water jet cutting considering the variation in bore diameter of focussing nozzle. Proc 21st AIMTDR, Vellore (India) Dec 20–22:887–893

Wang GJ, Chou MH (2005) A neural-Taguchi-based quasi time-optimization control strategy for chemical-mechanical polishing processes. Int J Adv Manuf Technol 26:759–765 DOI 10.1007/s00170-003-1859-8

Sen M, Shan HS (2006) Optimal selection of machining conditions in the electro-jet drilling process using hybrid NN-DF-GA approach. Int J Mater Manuf Proc

Barua PB, Kumar P, Gaindhar JL (1997) Optimal setting of process parameters for multi-characteristic products using Taguchi design and utility-concept-an approach. Proc ICAMIE, University of Roorkee(India) Feb 6-8:839-842

Tarng YS, Yang WH (1998) Optimisation of the weld bead geometry in gas tungsten arc welding by the Taguchi method. Int J Adv Manuf Technol 14:549–554 DOI 10.1007/BF01301698

Lin TR (2002) Optimisation technique for face milling stainless steel with multiple performance characteristics. Int J Adv Manuf Technol 19:330–335 DOI 10.1007/s001700200021

Singh S, Shan HS, Kumar P (2002) Parametric optimization of magnetic-field assisted abrasive flow machining by the Taguchi method. Qual Rel Eng Int 18:273–283 DOI 10.1002/qre.470

Tosun N, Ozler L (2004) Optimisation for hot turning operations with multiple performance characteristics. Int J Adv Manuf Technol 23:777–782 DOI 10.1007/s00170-003-1672-4

Bunn DW (1982) Analysis for optimal decisions. Wiley, New York

Gupta V, Murthy PN (1980) An introduction to engineering design method. Tata McGraw-Hill, New Delhi

Roy RK (1990) A primer on the Taguchi method. Competitive Manufacturing Series, Van Nostrand Reinhold, New York

Dubey AK (2008) A hybrid approach for multi-performance optimization of the electro-chemical honing process. Int J Adv Manuf Technol, DOI 10.1007/s00170-008-1422-8

Dubey AK (2008) Multi- performance modeling & optimization control strategies for electro-chemical honing: a critical evaluation. Int J Adv Manuf Technol, DOI 10.1007/s00170-008-1477-6

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dubey, A.K. Multi-response optimization of electro-chemical honing using utility-based Taguchi approach. Int J Adv Manuf Technol 41, 749–759 (2009). https://doi.org/10.1007/s00170-008-1525-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-008-1525-2