Abstract

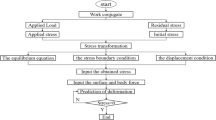

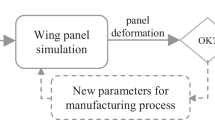

The civil aircraft industry often assembles large deformable aluminium components within the fuselage and wing structures. Part-to-part assembly of these compliant components regularly causes difficulties associated with dimensional variations. This paper describes a methodology to predict overall deformation between the alignment of the rib foot and the skin panel. The assembly operations and conditions encountered on the real production jigs were conducted under simulated laboratory conditions. A table method for prediction was developed to reduce uncertainties in positioning between the skin panel and rib foot. Finite element model of the rib was created to further enhance the prediction method. Results obtained from the predicted method were evaluated against real factory data. The validation performed against the assembly plant showed good performance of the prediction method in forecasting the positional variations occurring during the simulation of the assembly. The prediction method was, therefore, proven to be reliable.

Similar content being viewed by others

References

Cretin L, Saadat M (2001) On variation minimisation during aerospace assembly. In Third World Manufacturing Congress, International Symposium on Manufacturing Technology, Rochester, USA, pp. 24–27

Jeffreys D, Leaney PG (1998) A dimensional control methodology for the variation analysis of aircraft structure assembly. In Advance in Manufacturing Technology XII. Proceedings of the Fourteenth National Conference on Manufacturing Research, Derby, pp. 777–783

Dahlstrom S, Soderberg R (2001) Towards a method for early evaluations of sheet metal assemblies. The 7th CIRP International Seminar on Computer Aided Tolerancing, ENS de Cachan, France

Sellem E, Riviere A (1998) Tolerance analysis of deformable assemblies. Proceedings of DETC98: 1998 ASME Engineering Technical Conference, Atlanta, GA

Sellem E, Riviere A, Charles AD, Clement A (1999) Validation of the tolerance analysis of compliant assemblies. Proceedings of DETC99: 1999 ASME Engineering Technical Conference, Las Vegas, Nevada

Camelio JA, Hu SJ, Ceglarek DJ (2001) Modelling variation propagation of multi station assembly systems with compliant parts. Proceedings of DETC01: 2001 ASME Engineering Technical Conference, Pittsburgh, Pennsylvania

Saadat M, Cretin L (2002a) Measurement systems for large aerospace components. Sensor Review 22(3):199–206 DOI 10.1108/02602280210433025

Saadat M, Cretin L (2002b) Dimensional variation during Airbus wing assembly. Assemb Autom 22(3):270–276 DOI 10.1108/01445150210436482

Marwin AB (2002) Wing skin panel miller upgraded. Manufacturing Talk, Case study/Application note, Issue 13, May 2002

Society of Automotive Engineering (2001) Manual on Shot Peening - 2001 Edition. ISBN Number: 0–7680–0868–9, Date Published: August 2001, Product Code: HS-84/2001

Austin W (2005) Assembling the super jumbo. Assembly 48(9):66–77

Morrison R (1999) Weird and Wonderful Applications of Close-Range Digital Photogrammetry. CMSC’99, Seattle, July 26–30

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Saadat, M., Cretin, L., Sim, R. et al. Deformation analysis of large aerospace components during assembly. Int J Adv Manuf Technol 41, 145–155 (2009). https://doi.org/10.1007/s00170-008-1464-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-008-1464-y