Abstract

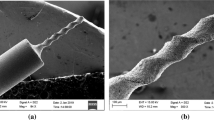

In this study, a two-step composite processing technology combining the EDM process and electrochemical etching is introduced to fabricate a micro-electrodes array. Firstly, rectangular columns measuring 0.2×0.2 mm are machined by the wire-EDM (electrical discharge machining) machine tool, then electrochemical etching is used to erode the microelectrodes array into cylindrical columns. Results show that microelectrodes ranging from hundreds of micrometers to several millimeters could be prepared. Then the machined microelectrodes are used as a cathode tool for electrochemical drilling of micro-hole arrays in electrochemical micromachining (EMM). Furthermore, various parameters affecting the performance of EMM are discussed in detail. Results indicate that the production of EMM improves by using multiple microelectrodes. The pulse current shows strong localization in micro-hole drilling and improves the machining accuracy.

Similar content being viewed by others

References

Datta M, Landolt D (2000) Fundamental aspects and applications of electrochemical microfabrication. Electrochim Acta 45:2535–2558

Landolt D, Chauvy PF, Zinger O (2003) Electrochemical micromachining, polishing and surface structuring of metals: fundamental aspects and new developments. Electrochim Acta 48(20–22):3185–3201

Lee ES, Baek SY, Cho CR (2007) A study of the characteristics for electrochemical micromachining with ultrashort voltage pulses. Int J Adv Manuf Technol 31:762–769

Asokan P, Kumar RR, Jeyapaul R, Santhi M (2007) Development of multi-objective optimization models for electrochemical machining process. Int J Adv Manuf Technol

Hocheng H, Kao PS, Lin SC (2005) Development of the eroded opening during electro chemical boring of hole. Int J Adv Manuf Technol 25:1105–1112

Schuster R, Kirchner V, Allongue P, Ertl G (2000) Electrochemical Micromachining. Science 289:98–101

Bhattacharyya B, Mitra S, Boro AK (2002) Electrochemical machining: New possibilities for micromachining. Robot Comput-Integr Manuf 18(3–4):283–289

Takahata K, Yogesh B (2002) Gianchandani. Batch mode micro-electro-discharge machining. J Microelectromech Syst 11:102–110

Kim BH, Park BJ, Chu CN (2006) Fabrication of multiple electrodes by reverse EDM and their application in micro ECM. J Micromech Microeng 16(4):843–850

Weng FT (2006) Electrodischarge machining of a coaxial array of microholes using a graphite-copper electrode. Int J Adv Manuf Technol 27:1097–1100

Weng FT, Her MG (2002) Study of the batch production of micro parts using the EDM Process. Int J Adv Manuf Technol 19(4):266–270

Weng FT (2004) Fabrication of microelectrodes for EDM machining by a combined etching process. J Micromech Microeng 14(5):N1–N4

Wang ZL, Zhu BG, Cao GH (2005) Fabricating microelectrode by electrochemical micromachining. Proc SPIE 6041:1–5

Lim YM, Kim SH (2001) An electrochemical fabrication method for extremely thin cylindrical micropin. Int J Mach Tools Manuf 4:2287–2296

Wang MH, Zhu D, Zhang ZY (2006) Fabrication of micro-pin based on electrochemical etching. Chin J Mech Eng 42(6):128–132

Jain VK, Rajurkar KP (1991) An integrated approach for tool design in ECM. Prec Eng 13(2):111–124

Rajurkar KP, Kozak J, Wei B (1993) Study of pulse electrochemical machining characteristics. Ann CIRP 42(1):231–234

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, M.H., Zhu, D. Fabrication of multiple electrodes and their application for micro-holes array in ECM. Int J Adv Manuf Technol 41, 42–47 (2009). https://doi.org/10.1007/s00170-008-1456-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-008-1456-y