Abstract

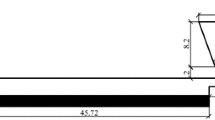

A three-dimensional numerical model, developed on the basis of the finite difference method and the volume fluid method, is used to analyze the mechanism of the liquid metal flow and the possibility of air entrapment in the injection chamber of die casting machine during the slow shot stage. The model gives designers a clear overall picture of the slow shot process and enables them to optimize the injection parameters.

Similar content being viewed by others

References

Garber LW (1982) Theoretical analysis and experimental observation of air entrapment during cold chamber filling, Die Casting Engineer, May–June, 14–22

Thome MC, Brevick JR (1993) Modeling fluid flow in horizontal cold chamber die casting shot sleeves. AFS Trans 101:343–348

Brevick JR, Armentrout DJ, Chu Y (1994) Minimization of entrained gas porosity in aluminum horizontal cold chamber die casting. NAMRI/SME Trans 22:41–46

Tszeng TC, Chu YL (1994) A study of wave formation in shot sleeve of a die casting machine. ASME J Eng Ind 116(2):175–182

Karni Y (1991) Selection of process variables for die casting, Ph.D. thesis. Ohio State University

Duran M, Karni Y, Brevick J, Chu Y, Altan T (1991) Minimization of air entrapment in the shot sleeve of a die casting machine to reduce porosity, Technical Report ERC/NSM-C-91–31. Ohio State University

Jiangou Z (2004) Finite element analysis of flow and heat transfer of molten metal during the slow shot of die casting, Doctoral thesis. Carleton University

Nichols BD, Hirt CW, Romero NC (1975) Numerical solution algorithm for transient fluid flows, Los Alamos Scientific Laboratory Report LA-5852

Nichols BD, Hirt CW (1980) A solution algorithm for transient fluid flow with multiple free boundaries, Los Alamos Scientific Laboratory Report LA-8355

Elliot SD (1999) Fluid flow aspects of solidification modeling: Simulation of low pressure die casting, Ph.D. Thesis, Department of Mining & Metallurgical Engineering, University of Queensland

Babaei R, Abdollahi J, Homayonifar P (2006) Improved advection algorithm of computational modeling of free surface flow using structured grids. Comput Methods Appl Mech Eng 195:775–795

Gengsheng W (2005) A Fixed-mesh method for general moving objects, Flow Science Inc., August

Fox RW, McDonald AT (1994) Introduction to fluid mechanics, Wiley, New York

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jalili Nikroo, A., Akhlaghi, M. & Ahmadi Najafabadi, M. Simulation and analysis of flow in the injection chamber of die casting machine during the slow shot phase. Int J Adv Manuf Technol 41, 31–41 (2009). https://doi.org/10.1007/s00170-008-1444-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-008-1444-2