Abstract

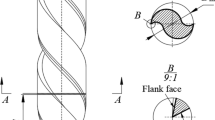

Cutting tool wear is well known to affect the surface finish of a turned part. Various machine vision methods have been developed in the past to measure and quantify tool wear. The two most widely measured parameters in tool wear monitoring are flank wear and crater wear. Works carried out by several researchers recently have shown that notch wear has a more severe effect on the surface roughness compared to flank or crater wear. In this work, a novel gradient detection approach has been developed to detect the presence of micro-scale notches in the nose area of the cutting tool. This method is capable of detecting the location of the notch accurately from a single worn cutting tool image.

Similar content being viewed by others

References

Kurada S, Bradley C (1997) A review of machine vision sensors for tool condition monitoring. Computer in Industry 34:55–72

Kurada S, Bradley C (1997) A machine vision system for tool wear assessment. Tribol Int 30:295–304

International Standard (1993) Tool-life testing with single-point turning tools: ISO 3685 2nd Edition, Switzerland

Wang WH, Hong GS, Wong YS (2006) Flank wear measurement by threshold independent method with sub-pixel accuracy. Int J Mach Tools Manuf 46:199–207

Wang WH, Wong YS, Hong GS (2005) Flank wear measurement by successive image analysis. Computer in Industry 56:816–830

Pfeifer T, Wiegers L (2000) Reliable tool wear monitoring by optimized image and illumination control in machine vision. Measurement 28:209–218

Sortino M (2003) Application of statistical filtering for optical detection of tool wear. Int J Mach Tools Manuf 43:493–497

Jeon JU, Kim SW (1988) Optical flank wear monitoring of cutting tools by image processing. Wear 127:207–217

Wang WH, Wong YS, Hong GS (2006) 3D measurement of crater wear by phase shifting method. Wear 261:164–171

Jurkovic J, Korosec M, Kopac J (2005) New approach in tool wear measuring technique using CCD vision system. Int J Mach Tools Manuf 45(2005):1023–1030

Ghani AK, Choudhury IA, Husni (2002) Study of tool life, surface roughness and vibration in machining nodular cast iron with ceramic tool. J Mater Process Technol 127:17–22

Pavel R, Marinescu J, Deis M, Pillar J (2005) Effect of tool wear on surface finish for a case of continuous and interrupted hard turning. J Mater Process Technol 170(3):341–349

Kwon Y, Fischer GW (2003) A novel approach to quantifying tool wear and tool life measurements for optimal tool management. Int J Mach Tools Manuf 43:359–368

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shahabi, H.H., Low, T.H. & Ratnam, M.M. Notch wear detection in cutting tools using gradient approach and polynomial fitting. Int J Adv Manuf Technol 40, 1057–1066 (2009). https://doi.org/10.1007/s00170-008-1437-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-008-1437-1