Abstract

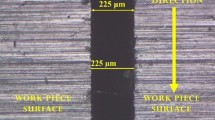

Currently, many kinds of ceramics are used in advanced industrial fields due to their superior mechanical properties, such as thermal, wear, corrosion resistance, and lightweight features. Wire saw machining ceramic (Al2O3) was investigated by ultrasonic vibration in this study. Taguchi approach is a powerful design tool for high-quality systems. Material removal rate, wafer surface roughness, steel wire wear, kerf width, and flatness during machining ceramic were selected as quality character factors to optimize the machining parameters (swinging angle, concentration, mixed grain and direction of ultrasonic vibration) to get the larger-the-better (material removal rate) and the smaller-the-better (wafer surface roughness, steel wire wear, kerf width and flatness) machining characteristics by Taguchi method. The results indicated that wire swinging produces a higher material removal rate and good wafer surface roughness. Ultrasonic vibration improved material removal rate, without affecting the flatness under different machining conditions. Experimental results show that the optimal wire saw machining parameters based on grey relational analysis can be determined effectively and material removal rate increases from 2.972 to 3.324 mm2/min, wafer surface roughness decreases from 0.37 to 0.34 μm, steel wire wear decreases from 0.78 to 0.77 μm, kerf width decreases from 0.352 to 0.350 mm, and flatness decreases from 7.51 to 7.22 μm are observed.

Similar content being viewed by others

References

Hsu CY (2000) The study of wire saw machining (in Chinese). Doctoral Thesis University of Taiwan

Bhagavat S, Kao I (2006) Theoretical analysis on the effects of crystal anisotropy on wiresawing process and application to wafer slicing. Int J Mach Tools Manuf 46(5):531–541

Yamamoto T (1995) Multi-wire slabbing of granite. Ind Diam Rev 55(567):179–181

Contardi GL (1993) Wire saw beads economic production. Ind Diam Rev 53(558):256–260

Kojima M (1990) Development of new wafer slicing equipment. Sumitomo Met 42(4):218–224

Suwabe H, Ishikawa KI, Miyashita T (1997) A study of the processing characteristics of a swinging multi-wire saw-regarding the effects of slurry composition. Int Conf on Precision Eng 1:253–256

Clark WI, Shih AJ, Lemaster RL, McSpadden SB (2003) Fixed abrasive diamond wire machining, part II: experiment design and results. Int J Mach Tools Manuf 43:533–542

Phillip JR (1989) Taguchi techniques for quality engineering. McGraw-Hill, New York

Wang CC, Yan BH (2000) Blind-hole drilling of Al2O3/6061 Al composite using rotary electro-discharge machining. J Mater Process Technol 102:90–102

Lin JL, Lin CL (2002) The use of the orthogonal array with grey relational analysis to optimize the electrical discharge machining process with multiple performance characteristics. Inter J Mach Tools Manuf 42(2):237–244

Tosun N (2006) Determination of optimum parameters for multi-performance characteristics in drilling by using grey relational analysis. Int J Adv Manuf Technol 28:450–455

Chang CK, Lu HS (2007) Design optimization of cutting parameters for side milling operations with multiple performance characteristics. Int J Adv Manuf Technol 32:18–26

Tarng YS, Juang SC, Chang CH (2006) The use of grey-based Taguchi methods to determine submerged arc welding process parameters in hardfacing. J Mater Process Technol 128:1–6

Deng JL (1992) The essential method of grey systems. HUST Press, Wuhan, China

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hsu, C.Y., Chen, C.S. & Tsao, C.C. Free abrasive wire saw machining of ceramics. Int J Adv Manuf Technol 40, 503–511 (2009). https://doi.org/10.1007/s00170-007-1355-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-007-1355-7