Abstract

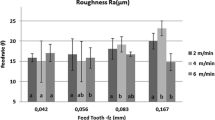

Medium density fibreboard (MDF) is an industrial wood product. It is made out of wood waste fibres glued together with resin by heat and pressure. Nowadays MDF products are preferred over solid wood in many applications due to certain comparative advantages. Milling is the machining operation frequently used in manufacturing parts of MDF. The aim of this article is to study the influence of cutting parameters (cutting speed and feed rate) on surface roughness in MDF milling. A plan of MDF milling experiments was performed with prefixed cutting parameters. The objective was to establish correlation between cutting speed and feed rate with the surface roughness in MDF panels after milling. The surface roughness decreases with an increase of spindle speed and increases with the feed rate. The milling tests showed the important role spindle speed plays on the evolution of the surface roughness as a function of material removal rate (MRR). The advantage of using a high cutting speed in MDF milling is evident.

Similar content being viewed by others

References

Hiziroglu S, Kosonkorn P (2006) Evaluation of surface roughness of Thai medium density fiberboard. Build Environ 41:527–533

Dippon J, Ren H, Amara FB, Altintas Y (2000) Orthogonal cutting mechanics of medium density fibreboards. Forest Prod J 50(7/8):25–30

Aguilera A, Meausoone PJ, Martin P (2000) Wood material influence in routing operations: the MDF case. Holz als Roh - und Werkstoff 58:278–283

Lin RJ, van Houts J, Bhattacharyya D (2006) Machinability investigation of medium-density fibreboard. Holzforschung 60:71–77

Gordon S, Hillery MT (2003) A review of the cutting of composite materials. Proc IME J Mater Des Appl 217:35–45

Engin S, Altintas Y, Amara FB (2000) Mechanics of routing medium density fiberboard. Forest Prod J 50(9):65–69

Philbin P, Gordon S (2006) Recent research on the machining of wood-based composite materials. International Journal of Machining and Machinability of Materials 1(2):186–201

Miklaszewski S, Zurek M, Beer P, Sokolowska A (2000) Micromechanism of polycrystalline cemented diamond tool wear during milling of wood-based materials. Diam Relat Mater 9:1125–1128

Davim JP, Clemente VC, Silva S (2007) Drilling investigations of MDF (medium density fibreboard). J Mater Process Technol (in press)

Davim JP, Clemente VC, Silva S (2007) Evaluation of delamination in drilling MDF (medium density fibreboard). Proc Inst Mech Eng, B J Eng Manuf 221(4):655–658

Davim JP, Campos Rubio J, Abrao AM (2007) Delamination assessment after drilling medium density fibreboard (MDF) using digital image analysis. Holzforschung 61(3):294–300

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Davim, J.P., Clemente, V.C. & Silva, S. Surface roughness aspects in milling MDF (medium density fibreboard). Int J Adv Manuf Technol 40, 49–55 (2009). https://doi.org/10.1007/s00170-007-1318-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-007-1318-z