Abstract

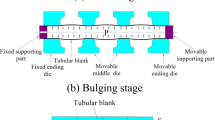

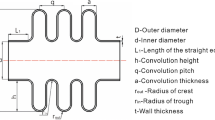

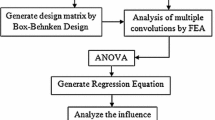

The manufacturing of metal bellows with high ratios of crown-to-root diameters is very sensitive to design parameters such as internal pressure inside the tube, axial force and movement, die-stroke length (distance of the dies) as well as the initial tube length. In this study a metal bellows is simulated with FEM using a commercial code (ABAQUS/Explicit) in order to find the optimum design parameters. Using the estimated design parameters lead to a product with acceptable quality. In this work, the manufacturing of metal bellows consists of only bulging and folding stages. After the folding process, internal pressure, axial force and annular plate dies are removed and the length of the bellows increases due to spring back. The quality of the final product depends on the amount of spring back, crown diameter, and thickness distribution. The results obtained from the experiment show very good agreement with the results of FEM.

Similar content being viewed by others

References

Broman GI, Jonsson AP, Hermann MP (2000) Determining dynamic characteristics of bellows by manipulated beam finite elements of commercial software. Int J Press Vessels Piping 77:445–453

Satoshi I, Hiroshi K, Masanori K (2000) Evaluation of mechanical behavior of new type bellows with two directional convolutions. Nucl Eng Des 197:107–114

Becht C IV (2000) Fatigue of bellows a new design approach. Int J Press Vessels Piping 77:843–850

Zhu YZ, Wang HF, Sang ZF (2005) The effect of environmental medium on fatigue life for U-shaped bellows expansion joints. Int J Fatigue 28 (1):28–32

Jakubauskas V, Werner DS (1999) Transverse natural frequencies and flow induced vibrations of double bellows expansion joints. J Fluids Struct 13:461–479

Lee SW (2002) Study on the forming parameters of the metal bellows. J Mater Process Technol 130–131:47–53

Abhay KJ, Diwakar V, Sreekumar K (2003) Stress corrosion cracking of stainless-steel bellows of satellite launch vehicle propellant tank assembly. Eng Fail Anal 10:699–709

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Faraji, G., Besharati, M.K., Mosavi, M. et al. Experimental and finite element analysis of parameters in manufacturing of metal bellows. Int J Adv Manuf Technol 38, 641–648 (2008). https://doi.org/10.1007/s00170-007-1122-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-007-1122-9