Abstract

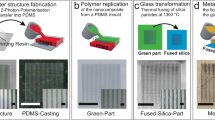

Different variants of reaction moulding techniques exploiting the rapid light-induced photopolymerisation of reactive resins are widely used in microsystem technologies for the fabrication of plastic components or for rapid prototyping (RP) purposes. In this paper, the further development of micro reaction moulding with respect to a rapid prototyping of ceramic and metal parts will be described. As in powder injection moulding, the process sequence binder–filler–formulation, replication, debinding and sintering has to be passed. The mould filling and, hence, the accurate reproduction of surface details depend strongly on the composite’s viscosity, which is a function of the filler load. Especially, an improved process control of the composite formation prior to moulding and the thermal debinding is crucial for the realisation of microstructured ceramic or metal parts. The development of the whole process chain and some examples will be presented.

Similar content being viewed by others

References

Wohlers TT (2000) Wohlers report 2000. Wohlers Associates, Fort Collins, Colorado

Gebhardt A (2000) Rapid prototyping. Hanser, Munich, Germany

Ikuta K, Hitowatari K (1992) Photo fabricated three dimensional micro fabrication. In: Proceedings of the JSME Annual Conference on Robotics and Mechatronics (ROBOMEC’92), June 1992, Kawasaki, Japan, pp 545–546

Kawata S, Sun H-B, Tanaka T, Takada K (2001) Finer features for functional microdevices. Nature 412(6848):697–698

Straub M, Nguyen LH, Fazlic A, Gu M (2004) Complex-shaped three-dimensional microstructures and photonic crystals generated in a polysiloxane polymer by two-photon microstereolithography. Opt Mater 27(3):359–364

PROFORM. Home page at http://www.proform.ch, January 2006

microTEC. Home page at http://www.microtec-d.de, January 2006

Focal Point Microsystems. Home page at http://fpmicro.com, January 2006

Bertsch A, Jiguet S, Renaud P (2004) Microfabrication of ceramic components by microstereolithography. J Micromech Microeng 14(2):197–203

Chartier T, Chaput C, Doreau D, Loiseau M (2002) Stereolithography of structural complex ceramic parts. J Mater Sci 37(15):3141–3147

Fischer P, Karapatis N, Romano V, Glardon R, Weber HP (2002) A model for the interaction of near-infrared laser pulses with metal powders in selective laser sintering. Appl Phys A 74(4):467–474

Chen C, Zuo T (2003) Microfabrication of micron metallic powder with laser sintering. Micronanoelectronic Technol 40(7–8):170–172

Microfabrica. Home page at http://www.microfabrica.com, January 2006

Hanemann T, Bauer W, Knitter R, Woias P (2006) Rapid prototyping and rapid tooling techniques for the manufacturing of silicon, polymer, metal and ceramic microdevices. In: Leondes CT (ed) MEMS/NEMS handbook: techniques and applications. Springer, Berlin, Germany, pp 187–255

Hanemann T, Ruprecht R, Haußelt J (1997) Micromolding and photopolymerization. Adv Mater 9(11):927–929

Hanemann T, Pfleging W, Haußelt J, Zum Gahr K-H (2002) Laser micromachining and light induced reaction injection molding as suitable process sequence for the rapid fabrication of microcomponents. Microsys Techn 7(5–6):209–214

Pfleging W, Hanemann T, Torge M, Bernauer W (2003) Rapid fabrication and replication of metal, ceramic and plastic mould inserts for application in microsystem technologies. J Mech Eng Sci 217(1):53–63

Merz L, Rath S, Piotter V, Ruprecht R, Hausselt J (2003) Powder injection molding of metallic and ceramic microparts. Microsys Techn 10(3):202–204

Thomas DG (1965) Transport characteristics of suspension: VIII. A note on the viscosity of Newtonian suspensions of uniform spherical particles. J Colloid Sci 20:267–277

Krieger IM, Dougherty TJ (1959) A mechanism for non-Newtonian flow in suspensions of rigid spheres. Trans Soc Rheol 3(1):137–152

Quemada D (1977) Rheology of concentrated disperse systems and minimum energy dissipation principle. I. Viscosity-concentration relationship. Rheol Acta 16(1):82–94

Hanemann T (2006) Influence of dispersants on the flow behaviour of unsaturated polyester—alumina composites. Composites A—Appl Sci Manufact 37(5):735–741

Einstein A (1906) Eine neue Bestimmung der Moleküldimension. Ann Physik 19:289–306 and Einstein A (1911) Berichtigung zu meiner Arbeit: Eine neue Bestimmung der Moleküldimension. Ann Physik 34:591–592

Hanemann, T (2006) Viscosity change of unsaturated polyester—alumina-composites using polyethylene glycol alkyl ether based dispersants. Composites A—Appl Sci Manufact 37(11):2155–2163

Hanemann T, Boehm J, Henzi P, Honnef K, Litfin K, Ritzhaupt-Kleissl E, Hausselt J (2004) From micro to nano: properties and potential applications of micro- and nano-filled polymer ceramic composites in microsystem technology. IEE Proc Nanobiotechnology 151(4):167–172

Hanemann T, Honnef K, Haußelt J (2004) Rapid prototyping of ceramic microcomponents using nanosized alumina. In: Proceedings of Nanofair: New Ideas for Industry, Karlsruhe, Germany, November 2004, pp 175–178

Ritzhaupt-Kleissl E, Boehm J, Hausselt J, Hanemann T (2005) Process chain for tailoring the refractive index of thermoplastic optical materials using ceramic nanoparticles. Adv Eng Mater 7(6):540–545

Piotter V, Holstein N, Plewa K, Ruprecht R, Hausselt J (2004) Replication of micro components by different variants of injection molding. Microsys Techn 10(6–7):547–551

Piotter V, Finnah G, Plewa K, Ruprecht R, Hausselt J (2004) High-resistive micro components produced by high-pressure powder injection molding. In: Menz W, Dimov S (eds) 4M2005: Proceedings of the 1st International Conference on Multi-Material Micro Manufacture. Elsevier, Amsterdam, The Netherlands, pp 207–209

German RM (1990) Powder injection molding. Metal Powder Industries Federation, Princeton, New Jersey

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hanemann, T., Honnef, K. & Hausselt, J. Process chain development for the rapid prototyping of microstructured polymer, ceramic and metal parts: composite flow behaviour optimisation, replication via reaction moulding and thermal postprocessing. Int J Adv Manuf Technol 33, 167–175 (2007). https://doi.org/10.1007/s00170-007-0952-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-007-0952-9