Abstract

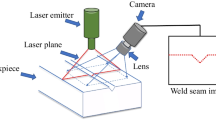

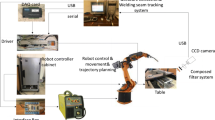

A novel circular laser three-dimensional (3D) scanner is developed instead of a one-dimensional laser spot scanner (1D) and two-dimensional (2D) striped laser light. Using the proposed circular laser scanner, a seam tracking system is constructed, and architecture based on the Visual C++ and RAPID languages which determines the cooperation among image processing modules is carried out. Finally, real seam tracking experiments are investigated and the error analysis is carried out. The results show that: (1) the proposed system can realize seam tracking; (2) the precision of this system is affected by the light scanning system, calibration results, image processing, and the welding seam 3D algorithm—the tracking accuracy is satisfied for robotic arc welding; (3) this system can be used in a welding robot system as a weld seam finder, flatness detector, and weld seam tracker.

Similar content being viewed by others

References

Laiping L, Shanben C, Tao L (2005) The modeling of welding pool surface reflectance of aluminum alloy pulse GTAW. Mater Sci Eng A 394(1–2):320–326

Kim JS, Son YT, Cho HS, Koh KI (1996) A robust visual seam tracking system for robotic arc welding. Mechatronics 6(2):141–163

Bae K-Y, Lee T-H, Ahn K-C (2002) An optical sensing system for seam tracking and weld pool control in gas metal arc welding of steel pipe. J Mater Process Technol 120(1–3):458–465

Bae K-Y, Park J-H (2006) A study on development of inductive sensor for automatic weld seam tracking. J Mater Process Technol 176(1–3):111–116

Yu J-Y, Na S-J (1997) A study on vision sensors for seam tracking of height-varying weldment. Part 1: mathematical model. Meccanica 7(7):599–612

Chen Y, Ip HHS (2006) Efficient extraction of metric measurements for planar scene under 2D homography with the help of planar circles. Mach Vis Appl 17(2):139–146

Xu PQ, Yang D, Zhao X, Yao S (2005) Study on filler metal (Ni-Fe-C) during GTAW of WC-30Co to 45" carbon steel. J Mater Sci 40(24):6559–6564

Xu PQ, Tang XH, Lu FG, Yao S (2006) Welded seam 3D calculation and seam location for welding robot system. Sci Technol Weld Join 11(3):352–357

Murtagh F, Raftery AE, Starck J-L (2005) Bayesian inference for multiband image segmentation via model-based cluster trees. Image Vis Comput 23(6):587–596

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xu, P., Xu, G., Tang, X. et al. A visual seam tracking system for robotic arc welding. Int J Adv Manuf Technol 37, 70–75 (2008). https://doi.org/10.1007/s00170-007-0939-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-007-0939-6