Abstract

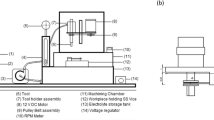

Electrical discharge diamond grinding (EDDG), which integrates diamond grinding and electro-discharge machining (EDM), is a new hybrid machining process for shaping electrically conductive very hard materials. The process employs synergetic interactive effect of electro-discharge action and abrasion action to increase machining performance. This paper presents an investigation on the experimental study and machining parameter design of electro-discharge diamond grinding (EDDG). The EDDG setup was designed and fabricated, and experiments were conducted on high speed steel (HSS) workpiece under varying current, pulse-ontime, duty factor and wheel speed. The settings of machining parameters were determined by using the Taguchi experimental design method. The level of the machining parameters on the MRR is determined by using analysis of variance (ANOVA). The optimum machining parameter combination was obtained by using the evaluated S/N ratio.

Similar content being viewed by others

References

Yadava V, Jain VK, Dixit PM (2002) Temperature distribution during electro discharge abrasive grinding. Machining Science and Technology-An International Journal 6(l):97–127

Aoyama T, Inasaki I (1986) Hybrid machining- combination of electrical discharge machining and grinding, Proc. of the 14th North American manufacturing research Conf., SME, pp 654–661

Kozak J, Kazimierz EO (2001) Selected problems of abrasive hybrid machining. J Mater Process Technol 109:360–366

Chaudhury SK, Jain VK, Gupta M (1999) Electrical discharge diamond grinding of high speed steel. Machining Science and Technology -An International Journal 3(1):91–105

Koshy P, Jain VK, Lal GK (1996) Mechanism of material removal in electrical discharge diamond grinding. Int J Mach Tools Manuf 1173–1185

Koshy P, Jain VK, Lal GK (1997) Grinding of cemented carbide with electrical spark assistance. J Mater Process Technol 72:61–68

Phadke MS (1989) Quality engineering using robust design. Prentice-Hall, Englewood Cliffs, NJ

Yuin Wu, Alan Wu (2000) Taguchi methods for robust design. ASME Press, New York

Sanjeev Kumar Singh Yadav (2004) Design, fabrication and experimental study of electrical discharge diamond grinding, M.Tech. Thesis, Motilal Nehru National Institute of Technology, Allahabad, India

Bhandari VB (1999) Design of machine elements. TMH Publishing Company Ltd., New Delhi, pp 417–453

P.S.G. (1999) Design data book, EWP Publications, Ed., pp 3.2–5.7

Ghosh A, Mallik AK (2001) Manufacturing science. EWP publications, New Delhi

Shaji S, Radhakrishnan V (2003) Analysis of process parameters in surface grinding with graphite as lubricant based on the Taguchi Method. J Mater Process Technol 141:51–59

Tang WH, Tarng YS (1988) Design optimization of cutting parameters for turning operations based on the Taguchi method. J Mater Process Technol 84:122–129

Kang J, Hadfield M (2001) Parameter optimization by Taguchi methods for finishing advanced ceramic balls using a novel eccentric lapping machine. Proc Inst Mech Eng 215-B:69–78

Komanduri R, Jiang M (1997) Application of Taguchi method for optimization of finishing conditions in magnetic float polishing. Wear 213(1–2):59–71

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kumar Singh Yadav, S., Yadava, V. & Lakshmi Narayana, V. Experimental study and parameter design of electro-discharge diamond grinding. Int J Adv Manuf Technol 36, 34–42 (2008). https://doi.org/10.1007/s00170-006-0820-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-006-0820-z