Abstract

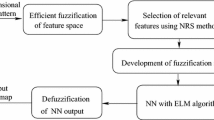

The purpose of this study is to develop an automated visual inspection system for analysis of the surface appearance of ring varistors based on an adaptive neuro-fuzzy inference system (ANFIS). Known image patterns of the six types of ring varistors are used in a training process to establish Sugeno FIS rules, and the input-output data are then set to train the ANFIS to tune the membership function. Feature extraction reduces image complexity using two-dimensional edge detection, calculated within divided rectangular region. The ANFIS combines the neural network adaptive capabilities and fuzzy logic qualitative to train a classification system for six different types of components. The performance of the ANFIS is evaluated in terms of training performance and classification accuracy. The results confirm that the proposed ANFIS is capable of classifying the six types of ring varistors with an accuracy of 98.67%.

Similar content being viewed by others

References

Gordon GG (1996) Automated glass fragmentation analysis. Machine vision applications in industrial inspection IV. Proc SPIE, San Jose, CA, pp 2665–2675

Caron J, Duvieubourg L, Postaire JG (1997) A hyperbolic filter for defect detection in packaging industry. In: Int conf quality control and artificial vision. Le Creusot, France, pp 207–211

Brzakovic D, Vujovic N (1992) Designing defect classification system: a cause study. Pattern Recogn 29:1401–1419

Fernandze C, Platero C, Campany P, Aracil R (1993) Vision system for online surface inspection in aluminum casting process. Proc IEEE International Conference on Industrial Electrics, Control, Instrumentation and Automation (IECON’93), pp 1854–1859

Caron J, Duvieubourg LJ, Orteu J, Revolte JG (1997) Automatic inspection system for strip of preweathered zinc. In: Int Conf applications of photonic technology. Montréal, Canada, pp 571–576

Torres T et al (1998) Automated real-time visual inspection system for high-resolution superimposed printings. Image Vis Comput 16:947–958

Guerra E, Villalobos JR (2001) A three-dimensional automated visual inspection system for SMT assembly. Comput Ind Eng 40:175–190

Chou PB, Rao AR, Wu FY (1997) Automatic defect classification for semiconductor manufacturing. Mach Vis Appl 4:201–214

Wilson D, Greig A, Gilby J, Smith R (1997) Using uncertainty techniques to aid defect classification in an automated visual inspection system. Industrial Inspection. IEE Colloquium 2/1–2/10

Kashitani A, Takanashi N, Tagawa N (1993) A solder joint inspection system for surface mounted pin grid arrays. In: Proc IEEE International conference on industrial electronics and instrumentation (IECON) ’93, Maui, HA, pp 1865–1870

Li H, Lin JC (1994) Using fuzzy logic to detect dimple defects of polished wafer surfaces. IEEE Trans Ind Appl 30:1530–1543

Sarigul E, Abbott AL, Schmoldt DL (2003) Rule-driven defect detection in CT images of hardwood logs. Comput Electron Agric 41:101–119

Chang J, Han G, Valverde JM, Griswold NC, Duque-Carrillo JF, Cork SE (1997) Quality classification system using a unified image processing and fuzzy-neural network methodology. IEEE Trans Neural Netw 8:964–973

Sarkodie-Gyan T, Lam CW, Hong D, Campbell AW (1997) An efficient object recognition scheme for a prototype component inspection. Mechatronics 7:185–197

Chen YH (1995) Computer vision for general purpose visual inspection: a fuzzy logic approach. Opt Lasers Eng 22:181–192

Jang JSR (1993) ANFIS: Adaptive-network-based fuzzy inference system. IEEE Trans Syst Man Cybern 23(3):665–685

Sonka M, Hlavac V, Boyle R (1999) Image processing, analysis, and machine vision. PWS Publishing, New York

Van GL, Wambacq P, Oostterlinck A (1991) Intelligence robotic vision systems. In: Intelligent robotic systems. Marcel Dekker, New York, pp 457–507

Morii F (2004) Distortion analysis on discrete Laplacian operators by introducing random images, image and graphics. Proc Third Int Conf, pp 80–83

Gunn SR (1999) On the discrete representation of the Laplacian of Gaussian. Pattern Recogn 32(8):1463–1472

Schwartz WH (1986) Vision system for PC board inspection. Assembly Eng 29(8):8–21

Moganti M, Ercal F (1995) Automatic PCB inspection system. IEEE Potentials 14(3):6–10

Chou PB, Rao AR, Sturzenbecker MC, Wu FY, Brecher VH (1997) Automatic defect classification for semiconductor manufacturing. Mach Vis Appl 9:201–214

Gonzalez RC, Woods RE (2002) Digital image processing, 2nd edn. Prentice Hall, Upper Saddle River, NJ

Demant G et al (1999) Industrial image processing–visual quality control in manufacturing. Springer, Berlin Heidelberg New York

Author information

Authors and Affiliations

Corresponding author

Additional information

This paper has not been published elsewhere nor has it been submitted for publication elsewhere.

Rights and permissions

About this article

Cite this article

Su, J.C., Tarng, Y.S. Automated visual inspection for surface appearance defects of varistors using an adaptive neuro-fuzzy inference system. Int J Adv Manuf Technol 35, 789–802 (2008). https://doi.org/10.1007/s00170-006-0756-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-006-0756-3