Abstract

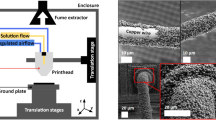

Established bubble-jet printheads consist of an assembly of three layers, which are a CMOS substrate, a channel layer and a nozzle layer. The aim of the presented work was to simplify the setup of bubble-jet printheads by means of integrating channel and nozzle structures in one single three-dimensional laser-structured polyimide nozzle plate. Different bonding techniques for an assembly onto 1/3 inch standard CMOS printhead substrates are validated. The main challenges are a variety of bonding materials, an alignment accuracy of <5 μm and the prevention of blocking the 20 μm deep fluidic channels in the polyimide which have minimal lateral dimensions of 10 μm and a minimal pitch of 15 μm. In total, three bonding techniques, with and without additional adhesion layers, were developed and evaluated. One method applies a 4 μm thick layer of Epotec 353ND (Polytec), a standard two-component epoxy, in a specifically adapted rolling manner onto the film that is subsequently aligned to the silicon chip using a flip-chip-bonder. Screen-printing and dispensing processes of adhesives were investigated but failed due to insufficient structural resolution. The second method uses photolithographic processes to produce structured adhesion preforms in SU-8 resist. With a layer thickness of 3 μm and an adapted curing schedule, promising results concerning resolution and contour accuracy were obtained. Thirdly, bonding without additional adhesion layers was achieved in a micro-sealing process that takes advantage of the highly defined thermoplastic softening of polyimide KJ (DuPont). The different processes were compared regarding to yield, printing behavior of the assembled printheads and applicability to high volume productions. The hereby developed adhesion technology was applied on the assembly of large one inch printheads for special applications.

Similar content being viewed by others

References

Li S et al (2003) Fabrication of micronozzles using low-temperature wafer-level bonding with SU-8. J Micromech Microeng 13:732–738

Guerin LJ et al (1997) Simple and low cost fabrication of embedded micro-channels by using a new thick-film photoplastic. Transducers 97, Chicago, IL, pp 1419–1422

Gadre AP et al (2003) Fabrication of an epoxy based multi-layer bio-fluidic dermal patch. Transducers ’03, Boston, MA, pp 806–809

Ruddy C (2003) Anwendungsspezifische Prozess-optimierung zum selektiven Bonden mit SU-8. Master Thesis, HSG-IMIT, Germany

Jiang K et al (2003) An ultrathick SU-8 process using UV-lithography. Polytronic, Montreux, pp 45–49

Paul BK et al (1999) Microlamination for micro-technology-based energy, chemical, and biological systems. ASME IMECE, Nashville, Tennessee, USA

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Goettsche, T., Ruddy, C., Heller, U. et al. Comparison of bonding procedures for 3D-structured polyimide films on silicon substrates applied to ink-jet cartridges. Int J Adv Manuf Technol 33, 191–197 (2007). https://doi.org/10.1007/s00170-006-0709-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-006-0709-x