Abstract

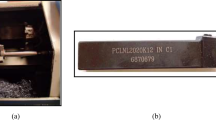

An experimental research study intended for the application of a planetary electrical discharge machining (EDM) process with copper-tungsten (Cu-W) electrodes in the surface micro-finishing of die helical thread cavities made with AISI H13 tool steel full-hardened at 53 HRC is presented. To establish the EDM parameters’ effect on various surface finishing aspects and metallurgical transformations, three tool electrode Cu-W compositions are selected, and operating parameters such as the open-circuit voltage (U 0), the discharge voltage (u e), the peak discharge current (î e), the pulse-on duration (t i), the duty factor (τ) and the dielectric flushing pressure (p in), are correlated. The researched machining characteristics are the material removal rate (MRR—V w), the relative tool wear ratio (TWR—ϑ), the workpiece surface roughness (SR—Ra), the average white layer thickness (WLT—e wl) and the heat-affected zone (HAZ—Z ha). An empirical relation between the surface roughness (SR—Ra) and the energy per discharge (W e) has been determined. It is analysed that copper-tungsten electrodes with negative polarity are appropriate for planetary EDM die steel surface micro-finishing, allowing the attaining of good geometry accuracy and sharp details. For die steel precision EDM, the relative wear ratio optimum condition and minor surface roughness takes place at a gap voltage of 280 V, discharge current of 0.5–1.0 A, pulse-on duration of 0.8 μs, duty factor of 50%, dielectric flushing pressure of 40 kPa and copper tungsten (Cu20W80) as the tool electrode material with negative polarity. The copper-tungsten electrode’s low material removal rate and low tool-wear ratio allows the machining of EDM cavity surfaces with an accurate geometry and a “mirror-like” surface micro-finishing. A planetary EDM application to manufacture helical thread cavities in steel dies for polymer injection is presented. Conclusions are appointed for the planetary EDM of helical thread cavities with Cu-W electrodes validating the accomplishment as a novel technique for manufacturing processes.

Similar content being viewed by others

References

Ho KH, Newman ST (2003) State of the art electrical discharge machining (EDM). Int J Mach Tools Manuf 43(13):1287–1300

Ho KH, Newman ST, Rahimifard S, Allen RD (2004) State of the art in wire electrical discharge machining (WEDM). Int J Mach Tools Manuf 44(12–13):1247–1259

Lazarenko BR (1944) Die Elektrodenfunkenbearbeitung von Metallen, Vestnik Maschinostroia, Moskau, no. 1 S.2536

König W, Wertheim R, Zvirin Y, Roren M (1975) Material removal and energy distribution in electrical discharge machining. Annals CIRP 24(1):95–100

Lin JL, Wang KS, Yan BH, Tarng YS (2000) Optimization of the electrical discharge machining process based on the Taguchi method with fuzzy logics. J Mater Process Technol 102(1):48–55

Lin CL, Lin JL, Ko TC (2002) Optimisation of the EDM process based on the orthogonal array with fuzzy logic and grey relational analysis method. Int J Adv Manuf Technol 19(4):271–277

Van Dijck F, Crookall JR, Heuvelman CJ, Snoyes R (1974) Some results of physical research in EDM. In: Proceedings of the 4th International Symposium for Electromachining, Bratislava, Poland, vol 1, pp 68–85

Zolotick BN (1970) Phänomenologische Theorie der Funkenerosiven Massbearbeitung. In: Proceedings of the International Symposium for Electromachining, Vien, Austria, vol 1, pp 185–191

Crookall JR, Khor BC (1974) Electro-discharge surfaces. In: Proceedings of the 15th International Machine Tool Design and Research Conference, England, September 1974, vol 1, pp 373–384

Dibitonto DD, Eubank PT, Mukunk RP, Barrufet MA (1989) Theorical models of the electrical discharge machining process I: a simple cathode erosion model. J Appl Phys 66(9):4095–4103

König W, Klocke F (1997) Fertigungsverfahren 3. Abtragen und Generieren. Springer, Berlin Heidelberg New York

Li L, Wong YS, Fuh JYH, Lu L (2001) Effect of TiC in copper-tungsten electrodes on EDM performance. J Mater Process Technol 113(1):563–567

Lee SH, Li XP (2001) Study of the effect of machining parameters on the machining characteristics in electrical discharge machining of tungsten carbide. J Mater Process Technol 115(3):344–358

Ferreira JC, Mateus AS (1999) Production of EDM electrodes via rapid prototyping. In: Proceedings of the IWK ’99 Congress, edition TU Ilmenau, Germany, vol. 3, pp 390–395

Zaw HM, Fuh JYH, Nee AYC, Lu L (1999) Formation of a new EDM electrode material using sintering techniques. J Mater Process Technol 89(90):182–186

Wong YS, Lim LC, Rahuman I, Tee WM (1998) Near-mirror-finish phenomenon in EDM using powder-mixed dielectric. J Mater Process Technol 79(1–3):30–40

Niwa S, Furuya M (1995) A study on optimum machining conditions in EDM process for making molds and dies/optimization of feeding and planetary motion of an electrode condition. In: Proceedings of the 11th International Symposium for Electromachining (ISEM-XI), Lausanne, Switzerland, April 1995

Ginzel J (2002) Funkenerosives Senken mit Neuro-Fuzzy Prozeßführung und Fehlentladungsbehandlung unter Berücksichtigung der Bahn- und Planetärerosion. Herbert Utz Verlag, München, Germany

VDI: Richtlinie 3402, Blatt 1 (1990) Elektroerosive Bearbeitung—Definitionen und Terminologie (Electrical discharge machining—definitions and terminology)

Yahya A, Manning CD (2004) Determination of material removal rate of an electro-discharge machine using dimensional analysis. J Phys D: Appl Phys 37(10):1467–1471

Narasimhan J, Yu Z, Rajurkar KP (2005) Tool wear compensation and path generation in micro and macro EDM. J Manuf Process 7(1)75–82

MatWeb. The Online Materials Information Resource. Home page at http://www.matweb.com

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ferreira, J.C. A study of die helical thread cavity surface finish made by Cu-W electrodes with planetary EDM. Int J Adv Manuf Technol 34, 1120–1132 (2007). https://doi.org/10.1007/s00170-006-0687-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-006-0687-z