Abstract

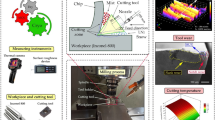

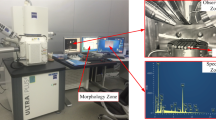

This study investigates the properties of machining MAR-M247 nickel-based superalloy combined ultrasonic vibration with high-temperature aided cutting. Taguchi experimental design was adopted to identify the influence of machining parameters on the machining characteristics. The six machining parameters, namely cutting tools for different materials; depth of cut; cutting speed; feed rate; working temperature; and, ultrasonic power. The machining characteristics analyzed include surface roughness, flank wear, cutting force, and milling temperature. According to the experimental results, when the cutting speed is greater than 90 m/min, P-type tungsten-carbide cutters with or without a Ti-alloy coating were unable to endure the very high temperatures generated in milling MAR-M247 nickel-based superalloy. The tungsten-carbide cutters melted and fractured. Due to the insufficient toughness of cermet cutters, the periodic high-impact stress causes severe cutter fractures when the cutting speed is greater than 60 m/min. When the cutting speed was less than 40 m/min, the cutter temperature was not significantly increased. Thus no melting or fracture of the cutters was found. Furthermore, when the cutting speed was less than 40 m/min, and fluid containing nano-particles of 5–23 nm in size was used, the cutter-workpiece friction force was reduced and the cutter life was extended.

Similar content being viewed by others

References

Chen YC, Liao YS (2003) Study on wear mechanisms in drilling of Inconel 718 superalloy. J Mater Process Technol 140:269–273

Choudhury IA, El-Baradie MA (1998) Machinability of nickel-base super alloys:a general review. J Mater Process Technol 77:278–284

Richards N, Aspinwall D (1989) Use of ceramic tools for machining nickel based alloys. Int J Mach Tools Manuf 29(4):575–588

Wayne SF, Buljan ST (1990) Wear of ceramic tools in nickel-based superalloy machining. Tribol Trans 33:618–626

Vigneau J, Boulanger JJ (1982) Behavior of ceramic tools during machining nickel-based alloys. Ann CIRP 31(1):35–39

Hanasaki S, Fujiwara J, Touge M, Hasegawa Y (1990) Tool wear of coated when machining a high nickel alloys. Ann CIRP 39(1):77–80

Bestwai MA, Wardany TI (1993) Performance of whiskey-reinforced ceramic tools in milling nickel-based superalloy. Ann CIRP 42(1):99–102

Richard N, Aspinwall D (1975) Use of ceramic tools for machining nickel based alloys. Int J Mach Tools Manuf 29(4):588–595

Weber H, Herberger J, Pilz R (1984) Turning of machinable glass ceramics with an ultrasonic vibration tool. Ann CIRP33(1):85–87

Wang LJ, Zhao J (1987) Influence on surface roughness in turning with ultrasonic vibration tool. Int J Mach Tools Manuf 27(2):181–190

Liu CS, Zhao B, Gao GF, Jiao F (2002) Research on the characteristics of the cutting force in the vibration cutting of a particle-reinforced metal matrix composites SiCp/Al. J Mater Process Technol 129:196–199

Babitsky VI, Kalashnikov AN, Meadow A, Wijesundara AAHP (2003) Ultrasonic assisted turning of aviation materials. Int J Adv Manuf Technol 132:157–167

Shaw MC (1996) Metal cutting principles. Oxford Science Publications, Oxford

Ross PJ (1988) Taguchi techniques for quality engineering. McGraw-Hill, New York

Wang CC, Yan BH (2000) Blind-hole drilling of Al2O3/6061 Al composite using rotary electro-discharge machining. J Mater Process Technol 102:90–102

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hsu, C.Y., Huang, C.K. & Wu, C.Y. Milling of MAR-M247 nickel-based superalloy with high temperature and ultrasonic aiding. Int J Adv Manuf Technol 34, 857–866 (2007). https://doi.org/10.1007/s00170-006-0657-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-006-0657-5