Abstract

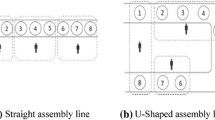

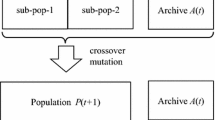

Evolutionary algorithms such as genetic algorithms have been applied on a variety of complex combinatorial optimization problems (COPs) with high success. However, in relation to other classes of COPs, there is little reported experimental work concerning the application of these heuristics on large size assembly line balancing problems (ALBPs). Moreover, very few works in the literature report comparative results on public benchmark instances of ALBPs for which upper bounds on the optimal objective function value exist. This paper considers the simple ALBP of type 2 (SALBP-2), which consists of optimally partitioning the tasks’ operations in an assembly line among the workstations with objective the minimization of the cycle time of the line. SALBP-2 is known to be intractable, and therefore the right way to proceed is through the use of heuristic techniques. To that purpose, a novel approach based on the differential evolution method has been developed and tested over public available benchmarks ALBPs. These benchmarks include test instances for several precedence graphs (representing the assembly restrictions) with up to 297 tasks. Extended comparisons with other previously published evolutionary computation methods showed a superior performance for the proposed approach.

Similar content being viewed by others

References

Kusiak A (2000) Computational intelligence in design and manufacturing. Wiley, New York

Scholl A (1999) Balancing and sequencing of assembly lines. Physica, Heidelberg, Germany

Becker C, Scholl A (2006) A survey on problems and methods in generalized assembly line balancing. Eur J Oper Res 168:694–715

Bukchin J, Dar-El EM, Rubinovitz J (2002) Mixed model assembly line design in a make-to-order environment. Comput Ind Eng 41:405–421

Meyr H (2004) Supply chain planning in the German automotive industry. OR Spectrum 26:447–470

Baybars I (1986) A survey of exact algorithms for the simple assembly line balancing problem. Manage Sci 32:909–932

Klein R, Scholl A (1996) Maximizing the production rate in simple assembly line balancing - a branch and bound procedure. Eur J Oper Res 91:367–385

Michalewicz Z, Fogel DB (2000) How to solve it: modern heuristics. Springer, Berlin Heidelberg New York

Kirkpatrick S, Gelatt CD Jr, Vecchi MP (1983) Optimization by simulated annealing. Science 220:671–680

Glover F (1989) Tabu-search-Part I. ORSA J Comput 1(3):190–206

Glover F (1990) Tabu-search-Part II. ORSA J Comput 2(1):4–32

Anderson EJ, Ferris MC (1994) Genetic algorithms for combinatorial optimization: the assembly line balancing problem. ORSA J Comput 6:161–173

Kim YK, Kim Y-J, Kim Y (1996) Genetic algorithms for assembly line balancing with various objectives. Comput Ind Eng 30/3:397–409

Watanabe T, Hashimoto Y, Nishikawa I, Tokumaru H (1995) Line balancing using a genetic evolution model. Control Eng Pract 3:60–76

Heinrici A (1994) A comparison between simulated annealing and tabu search with an example from the production planning. In: Dyckhoff H et al (eds) Operations Research Proceedings 1993, Springer, Berlin Heidelberg New York, pp 498–503

Scholl A, Voâ S (1996) Simple assembly line balancing - heuristic approaches. J Heuristics 2:217–244

Chiang W-C (1998) The application of a tabu search metaheuristic to the assembly line balancing problem. Ann Oper Res 77:209–227

Erel E, Sarin S (1998) A survey of the assembly line balancing procedures. Prod Plan Control 9(5):414–434

Rekiek B, Dolgui A, Delchambre A, Bratcu A (2002) State of the art of optimization methods for assembly line design. Annu Rev Control 26:163–174

Scholl A, Becker C (2006) State of the art exact and heuristic solution procedures for simple assembly line balancing. Eur J Oper Res 168(3):666–693

Storn R, Price K (1997) Differential evolution - a simple and efficient heuristic for global optimization over continuous spaces. J Glob Optim 11(4):341–354

Ali MM, Törn A (2004) Population set-based global optimization algorithms: some modifications and numerical studies. Comput Oper Res 31:1703–1725

Kaelo P, Ali MM (2006) A numerical study of some modified differential evolution algorithms. Eur J Oper Res 171:674–692

Nearchou AC (2006) Meta-heuristics from nature for the loop layout design problem. Int J Prod Econ 101/2:312–328

Onwubolu GO, Davendra D (2006) Scheduling flow shops using differential evolution. Eur J Oper Res 169:1176–1184

Bean J (1994) Genetics and random keys for sequencing and optimization. ORSA J Comput 6(2):154–160

Gen M, Cheng R (2000) Genetic algorithms and engineering optimization. Wiley, New York

Warshall S (1962) A theorem of a Boolean matrix. J ACM 9:11–12

Goncalves JF, De Almeida JR (2002) A hybrid genetic algorithm for assembly line balancing. J Heuristics 8(6):629–642

Zaharie D (2002) Critical values for the control parameters of differential evolution algorithms. In: Matoušek, Radek, Ošmera, Pavel (eds) Proc. of MENDEL 2002, 8th Int. Mendel Conference on Soft Computing, Brno, Czech Republic, pp 62–67

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nearchou, A.C. Balancing large assembly lines by a new heuristic based on differential evolution method. Int J Adv Manuf Technol 34, 1016–1029 (2007). https://doi.org/10.1007/s00170-006-0655-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-006-0655-7