Abstract

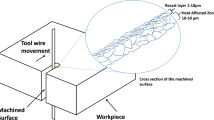

The material removal process in wire electrical discharge machining (WEDM) may result in work-piece surface damage due to the material thermal properties and the cutting parameters such as varying on-time pulses, open circuit voltage, machine cutting speed, and dielectric fluid pressure. A finite element method (FEM) program was developed to model temperature distribution in the workpiece under the conditions of different cutting parameters. The thermal parameters of low carbon steel (AISI4340) were selected to conduct this simulation. The thickness of the temperature affected layers for different cutting parameters was computed based on a critical temperature value. Through minimizing the thickness of the temperature affected layers and satisfying a certain cutting speed, a set of the cutting process parameters were determined for workpiece manufacture. On the other hand, the experimental investigation of the effects of cutting parameters on the thickness of the AISI4340 workpiece surface layers in WEDM was used to validate the simulation results. This study is helpful for developing advanced control strategies to enhance the complex contouring capabilities and machining rate while avoiding harmful surface damage.

Similar content being viewed by others

References

Wang WM, Rajurkar KP (1992) Modeling and adaptive control of EDM systems. J Manuf Syst 11(5):334–345

Ho KH, Newman ST (2003) State of the art electrical discharge machining (EDM). Advanced Manufacturing Systems and Technology Center, Wolfson School of Mechanical and Manufacture Engineering, UK

Chou YK, Evans CJ (1999) White layers and thermal modeling of hard turned surfaces. Int J Mach Tools Manuf 39(12):1863–1881

Wojtas AS, Suominen L, Shaw BA, Evans JT (1998) Detection of thermal damage in steel components after grinding using the magnetic Barkhausen noise method. Proceedings of the 7th ECNDT, Copenhagen, 3(9)

Velterop L (2003) Influence of wire electrical discharge machining on the fatigue properties of high strength stainless steel. National Aerospace Laboratory NLR, Amsterdam, The Netherlands

Blok H (1938) Theoretical study of temperature rise at surfaces of actual contact under oiliness lubricating conditions. Proceedings of general discussion on lubrication and lubricants. Institute of Mechanical Engineers, London, 2:222–235

Jaeger JC (1942) Moving sources of heat and the temperature at sliding contacts. J Proc Roy Soc NSW 76:133–228

Hahn RS (1951) On the temperature developed at the shear plane in the metal cutting process. Proceedings of the first US national congress of applied mechanics, ASME, pp 661–666

Erden A, Kaftanoglu B (1980) Heat transfer modeling of electric discharge machining. Proceeding of the 21st MTDR conference, Swansea, UK, pp 351–358

DiBitonto DD, Eubank PT, Patel MR, Barrufet A (1989) Theoretical models of the electrical discharge machining process -I: a simple cathode erosion model. J Appl Phys 66 (9):4104–4111

Scott D et al (1991) Analysis and optimization of parameter combination in wire electrical discharge machining process. Int J Prod Res 29(11):2189–2207

Biermann D et al (1997) Modeling and simulation of work-piece temperature in grinding by finite element method. Mach Sci Technol 1(2)

Bhattacharya R, Jain VK, Ghoshdastidar S (1996) Numerical simulation of thermal erosion in EDM process. J Inst Eng 77:13–19

Yadav V, Jain VK, Dixit PM (2002) Thermal stresses due to electrical discharge machining. Int J Mach Tools Manuf 42(8):887–888

Das S, Klotz M, Klocke F (2003) EDM simulation: finite element-based calculation of deformation, microstructure and residual stresses. J Mater Process Technol 142(2):434–451

Shi J (2004) Prediction of thermal damage in super finish hard machined surfaces. Dissertation, Purdue University, USA

Acknowledgements

This research was supported by the National Science Foundation’s Engineering Research Center for Reconfigurable Manufacturing Systems. The work is a partnership between the University of Michigan and Morgan State University in advanced manufacturing processes.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hargrove, S.K., Ding, D. Determining cutting parameters in wire EDM based on workpiece surface temperature distribution. Int J Adv Manuf Technol 34, 295–299 (2007). https://doi.org/10.1007/s00170-006-0609-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-006-0609-0