Abstract

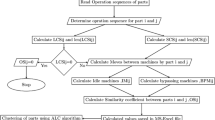

Reducing part redundancy because of design arbitrariness is an effective measure of improving production volume, of which part reengineering is a reasonable and effective approach. The problem was formalized, then similarity degree was measured by Euclidean proximity through considering similar rules of parts based on properties of isostructure, geometry, precision, material and performance indices. A similarity matrix could be constructed based on similarity degree, and part reengineering arithmetic was advanced based on fuzzy clustering. Finally, analysis and adjustment of part reengineering scheme was discussed. The strategy and method are effective in an instance of a motorcycle-hydraulic-disk brake disk reengineering.

Similar content being viewed by others

References

Paul G, Beitz W (1996) Engineering design. Springer, London

Chen YuK, Wang X-W, Huang S-X (1992) Practical group technology. Mechanical Industry Press, Beijing

O’Donnell FJ, MacCallum KJ, Hogg TD, Yu B (1996) Product structuring in a small manufacturing enterprise. Comput Ind 31(3):281–292

Tichem M, Storm T (1997) Designer support for product structuring-development of a DFX tool within the design coordination framework. Comput Ind 33(2–3):155–163

Hull FM, Collins PD, Liker JK (1996) Composite forms of organization as strategy for concurrent engineering effectiveness. IEEE Trans Eng Manage 43:133–142

Hansen CT, Riitahuhta A (2001) Issues on the development and application of computer tools to support product structuring and configuring. Int J Technol Manag 21(3):240–256

Ahmadi R, Roemer TA, Wang RH (2001) Structuring product development processes. Eur J Oper Res 130:539–558

Lau HCW, Jiang B, Chan FTS, Ip RWL (2002) An innovative scheme for product and process design. J Mater Process Technol 123:85–92

Yuval S, Yoram R (2006) Standardization and modularization driven by minimizing overall process effort. Comp Aided Des (in press)

Xue D, Dong Z (1997) Coding and clustering of design and manufacturing features for concurrent design. Comput Ind 34:139–153

Sarker BR (1996) The resemblance coefficients in group technology: a survey and comparative study of relational metrics. Comput Ind Eng 30(1):103–116

Sarker BR, Saiful Islam KM (1999) Relative performances of similarity and dissimilarity measures. Comput Ind Eng 37:769–807

Dowlatshahi S, Nagaraj M (1998) Application of group technology for design data management. Comput Ind Eng 34(1):235–255

Liao WT (2001) Classification and coding approaches to part family formation under a fuzzy environment. Fuzzy Sets Syst 122:425–441

Qi G-N, Shu B-H, Gu X-J et al (2000) Study on standardization and regularization technology of products. China Mech Eng 11(5):525–527

Pan S-X, Gao F, Feng P-E (2003) Module partition method research under the circumstances about mass customization. Chi Hsieh Kung Ch’eng Hsueh Pao 39(7):1–6

Wang X-Z, Ha M-H (2002) Fuzzy case study and fuzzy control. Hebei University Press, Baoding, China

Goonetillake JS, Camduff TW, Gray WA (2002) An integrity constraint management framework in engineering design. Comput Ind 48(1):29–44

Acknowledgements

This work is supported by the Zhejiang Provincial Natural Science Foundation of China under Grant No.Y105200 and Zhejiang Provincial Science and Technology Planning Key Project of China under Grant No.2006C21003.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gao, F., Xiao, G. & Zhang, Y. Strategy and method of part reengineering. Int J Adv Manuf Technol 34, 219–226 (2007). https://doi.org/10.1007/s00170-006-0602-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-006-0602-7