Abstract

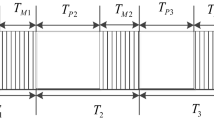

Manufacturing and production plants operate physical assets that deteriorate with usage and time, thus, maintenance actions are required to restore the assets back to their original predetermined operational conditions. In this paper, we extend previous work on maintenance scheduling to considering a multi-component system that optimises both cost and reliability simultaneously. The model uses the concept of imperfect maintenance and includes factors such as ageing due to the operation rate of the system, downtime for maintenance and lead time for spare parts. For each maintenance planning period, the model predicts which of the three possible actions (namely, maintaining the component, replacing the component or doing nothing) for each component should be taken, such that the reliability is at least at a required level and the net present cost for the entire planning period is minimised. The entire approach is illustrated through the use of a numerical example and the evaluation of the model is done by using an evolutionary algorithm.

Similar content being viewed by others

References

Price J (2002) The economics of repeated tube thickness surveys. Int J Press Vessel Pip 79(8):555–559

Noori S, Price J (2005) Case study of the use of API 581 on HK and HP material furnace tubes. J Press Vessel Technol 127(1):49–54

Chaudhuri D, Sahu KC (1977) Preventive maintenance intervals for optimal reliability of deteriorating systems. IEEE Trans Reliab 26(5):371–372

Jayabalan V, Chaudhuri D (1992) Cost optimization of maintenance scheduling for a system with assured reliability. IEEE Trans Reliab 41(1):21–25

Usher JS, Kamal AH, Syed WH (1998) Cost optimal preventive maintenance and replacement scheduling. IIE Trans 30(12):1121–1128

Wang H (2002) A survey of maintenance policies of deteriorating systems. Euro J Operational Res 139(3):469–489

Tsai YT, Wang KS, Tsai LC (2004) A study of availability-centered preventive maintenance for multi-component systems. Reliab Eng Syst Safety 84(3):261–270

Rao SS (1992) Reliability-based design. McGraw-Hill, New York

Cassady RC, Kutanoglu E (2005) Integrating preventive maintenance planning and production scheduling for a single machine. IEEE Trans Reliab 54(2):304–309

Sherwin DJ (2000) A critical analysis of reliability-centred maintenance as a management tool. In: Proceedings of the 4th International Conference of Maintenance Societies, Wollongong, Australia, May 2000

Jardine AKS, Tsang AHC (2005) Maintenance, replacement, and reliability: theory and applications. CRC Press/Taylor & Francis Group, Boca Raton, Florida

Wang H, Pham H (1997) Availability and optimal maintenance of series system subjected to imperfect repair. Int J Plant Eng Manage 2 (Chinese version)

Robert TP, Shahabudeen P (2004) Genetic algorithms for cost-effective maintenance of a reactor–regenerator system. Int J Adv Manuf Technol 23(11/12):846–856

Prins C (2004) A simple and effective evolutionary algorithm for the vehicle routing problem. Comput Oper Res 31(12):1985–2002

Goldberg DE (1989) Genetic algorithms in searching optimization, and machine learning, Addison-Wesley, Reading, Massachusetts

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tam, A.S.B., Chan, W.M. & Price, J.W.H. Maintenance scheduling to support the operation of manufacturing and production assets. Int J Adv Manuf Technol 34, 399–405 (2007). https://doi.org/10.1007/s00170-006-0593-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-006-0593-4