Abstract

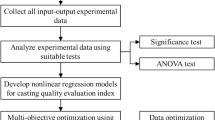

Squeeze casting is a hybrid metal forming process combining features of both casting and forging in one operation. This paper reports a research in which an attempt was made to prepare solid cylindrical components of LM24 aluminum alloy through squeeze casting. The primary objective was to investigate the effect of process parameters on the mechanical properties exhibited by the castings produced though squeeze casting process. A set of trials were conducted based on parameters settings suggested in Taguchi’s offline quality control concept. The experimental results indicate that the squeeze pressure and the die-preheating temperature were the parameters making significant contribution toward improvement in mechanical properties of squeeze cast LM24 aluminum alloy.

Similar content being viewed by others

References

Vijian P, Arunachalam VP (2005) Experimental study of squeeze casting of gunmetal. J Mater Process Technol 170:32–36

Yue TM, Chadwick GA (1996) Squeeze casting of the light alloys and their composites. J Mater Process Technol 58:302–307

Ghomashchi MR, Vikhrov A (2000) Squeeze casting:an overview. J Mater Process Technol 101:1–9

Kleiner K et al (2002) Microstructure and mechanical properties of squeeze cast and semi-solid cast Mg-Al alloys. J Lht Met 2:277–280

Brown JR, Barlow J et al (1994) Second report of Institute working group T20 casting process. Foundryman 87:386–390

Morton JR, Barlow J (1994) Squeeze casting from a theory to profit and a future. Foundryman 87:23–28

Yong MS, Clegg AJ (1999) Evaluation of squeeze cast magnesium alloy and composite. Foundryman, pp 71–75

Lynch RF, Olley R et al (1975) Squeeze casting of aluminum. AFS Trans 122:569–576

Yue TM (1997) Squeeze casting of high strength aluminum wrought alloy AA7010. J Mater Process Technol 66:179–185

Iwata Y, Sugiyama Y, Iwahori H, Awano Y (2000) Transferred pressure and shrinkage cavity of aluminum alloys on squeeze castings. J Japan Foundry Eng Soc 72:263–267

Basu K, Solonki RS, Muneshwar VS (1989) Squeeze casting of aluminum and its alloys. Indian Foundry October 25–34

Wu DH, Chang MS (2004) Use of Taguchi method to develop a robust design for the magnesium alloy die casting process. Mater Sci Eng A 379:366–371

Padmaprabha Seshan S (2005) Structure and properties of squeeze cast LM25 alloy. Foundry May/June 31–34

Avani Gandhi MS (2003) Problem solving using Taguchi DOE techniques. Ind Eng J XXXII:16–25

Taso CC, Hocheng H (2004) Taguchi analysis of delamination associated with various drill bits in drilling of composite material. Int J Mach Tools Manuf 44:1085–1090

Anastasiov KS (2002) Optimization of the aluminium die casting, process based on the Taguchi method. Proc Ins Mech Eng 216:969–977

Sung H Park (1996) Robust design and analysis quality engineering. Chapman and Hall, London

Ross PJ (1996) Taguchi techniques for quality engineering. McGraw-Hill, Singapore

Acknowledgements

The authors are thankful to the learned referees whose constructive comments and suggestions have been used to refine the previous version of this paper.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Vijian, P., Arunachalam, V.P. Optimization of squeeze casting process parameters using Taguchi analysis. Int J Adv Manuf Technol 33, 1122–1127 (2007). https://doi.org/10.1007/s00170-006-0550-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-006-0550-2