Abstract

It is believed that the acoustic emission (AE) signals contain potentially valuable information for tool wear and breakage monitoring and detection. However, AE stress waves produced in the cutting zone are distorted by the transmission path and the measurement systems and it is difficult to obtain an effective result by these raw acoustic emission data. In this article, a technique based on AE signal wavelet analysis is proposed for tool condition monitoring. The local characterize of frequency band, which contains the main energy of AE signals, is depicted by the wavelet multi-resolution analysis, and the singularity of the signal is represented by wavelet resolution coefficient norm. The feasibility for tool condition monitoring is demonstrated by the various cutting conditions in turning experiments.

Similar content being viewed by others

References

Annual Book of ASTM Standards, 03.03 (1990) “Nondestructive testing”, Section 3: Metals test methods and analytical procedures, E610-89a, Standard Terminology Relating to Acoustic Emission, pp. 269–271

Micheletti CF, Koenig W, Victor HR (1976) In-process tool wear sensors for cutting operations. Ann CIRP 25:483–496

Ravindra HV, Srinivasa YG, Krishnamurthy R (1993) Modeling for tool wear based on cutting forces in turing. Wear 169:25–32

Shiraishi M (1998) Scope of in-process measurement, monitoring and control techniques in machining process, part 1: In-process techniques for tools. Precis Eng 10(4):179–188

Damodarasamy S, Raman S (1993) Inexpensive system for classifying tool wear states using pattern recognition. Wear 170(2):149–160

Li X, Yuan Z (1998) Tool wear monitoring with wavelet packet transform-fuzzy clustering method. Wear 219(2):145–154

Yao YX, Li X, Yuan ZJ (1999) Tool wear detection with fuzzy classification and wavelet fuzzy neural network. Int J Mach Tools Manuf 39:1525–1538

Rangwala S, Dornfeld D (1987) Integration of sensors via neural networks for detection of tool wear states. Am Soc Mech Eng. Production Engineering Division (Publication) PED 25:109–120

Cho SS, Komvopoulos K (1997) Correlation between acoustic and wear of multi-layer ceramic coated carbide tool. Trans ASME 119:238–246

Liang S, Dornfeld D (1989) Tool wear detection using time series analysis of acoustic emission. J Eng Ind Trans ASME 111(3):199–205

Kannatey-Asibu E Jr, Dornfeld DA (1981) Quantitative relationship for acoustic emission from orthogonal metal cutting. Trans ASME 103:330–340

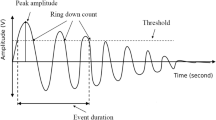

Gongtian Shen (2002) Parameter analysis of acoustic emission signals. J Non-Destruct Test 24(2):72 (in Chinese)

Ravindra H, Srinivasa Y, Krishnamurthy R (1997) Acoustic emission for tool condition monitoring in metal cutting. Wear 212(1):78–84

Li X, Yuan Z (1998) Tool wear monitoring with wavelet packet transform-fuzzy clustering method. Wear 219(2):125–154

Graps A (1995) An introduction to wavelets. IEEE Comp Sci Eng 2:2

Vetterli M, Herley C (1992) Wavelet and filter banks: theory and design. IEEE Trans Signal Process 40:2208–2232

Sun Q, Tang Y (2002) Singularity analysis using continuous wavelet transform for bearing fault diagnosis. Mech Syst Signal Process 16:1025–1041

Dong XZ, Geng ZX, Ge YZ et al (1997) Application of wavelet transform in power system fault signal analysis. Proc Chinese Society of Electrical Engineering 17:421–424 (in Chinese)

Jia QQ, Liu LG et al (2001) Abrupt change detection with wavelet for small current fault relaying. Proc Chinese Society of Electrical Engineering 21:78–82 (in Chinese)

Mallat S, Wang WL (1992) Singularity detection and processing with wavelets. IEEE Trans Inf Theory 38:617–643

Berman Z, Baras JS (1993) Properties of the multi-scale maxima and zerocrossing presentations. IEEE Trans Signal Process 41:3216–3231

Cvetkovic Z, Vetterli M (1995) Discrete-time wavelet extrema representation: design and consistent reconstruction. IEEE Trans Signal Process 43:681–693

Daubechies I (1992) Ten lectures on wavelet. Philadelphia, PA: Soc Ind Appl Math

Chen BH, Wang XZ, Yang SH, McGreavy C (1999) Application of wavelet and neural networks to diagnostic system development, 1, feature extraction. Comput Chem Eng 23:899–906

Glaser SD, Weiss GG, Johnson LR (1998) Body waves recorded inside an elastic half-space by an embedded, wideband velocity sensor. L Ac Soc Am 104(3 Part 1):1404–1412

Xiaoli Li (2002) A brief review: acoustic emission method for tool wear monitoring during turning. Int J Mach Tools Manuf 42:157–165

Grosse CU, Finck F, Kurz JH, Reinhardt H-W (2004) Improvements of AE technique using wavelet algorithms, coherence functions and automatic data analysis. Constr Build Mater 18:203–213

Acknowledgement

The work described in this paper was fully supported by the Natural Science Foundation of Shanghai, P. R. China (Project No. 02ZF14003).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, X., Li, B. Acoustic emission method for tool condition monitoring based on wavelet analysis. Int J Adv Manuf Technol 33, 968–976 (2007). https://doi.org/10.1007/s00170-006-0523-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-006-0523-5