Abstract

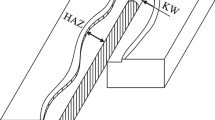

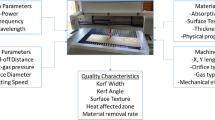

In some cases, in order to avoid interference during 3D laser cutting of thin metal a laser head could not be kept vertical to the surface of a work piece. In such situations, the cutting quality depends not only on “typical” cutting parameters but also on the slant angle of the laser head. Traditionally, many tests had to be done in order to obtain the best cutting results. In this paper, an experimental design is employed to reduce the number of tests and an artificial neural network (ANN) is set up to describe quantitatively the relationship between cutting quality and cutting parameters in the non-vertical laser cutting situation. A quality point system is used to evaluate the cutting result of the thin sheet quantitatively. Testing of this novel method shows that the calculated “quality point” using ANN is quite closely in accord with the actual cutting result. The ANN is very successful for optimizing parameters, predicting cutting results and deducing new cutting information.

Similar content being viewed by others

References

Cenna AA, Mathew P (2002) Analysis and prediction of laser cutting parameters of fibre reinforced plastics (FRP) composite materials. Int J Mach Tools Manuf 42(1)105–113

Lum KCP, Ng SL, Black I (2000) CO2 laser cutting of MDF: 1. Determination of process parameter settings. Opt Laser Technol 32(1)67–76

Chen S-L (1998) Analysis and modeling of reactive three-dimensional high-power CO2 laser cutting. Proc Instn Mech Eng B 212:113–128

Meijer CZ, Meijer J, Bakker EPM (1997) Process parameters for high-quality on-contour starting of laser cutting of steel. SPIE 3097:58–69

Abdulhadi E, Pelletier J-M, Lambertin M (1997) Development in laser cutting of steel: analytical modeling and experimental validation of the metallurgical effects. SPIE 3098:17–28

Bartl NL, Bergmann HW (1997) Influence of processing speed on cut quality in laser beam gas cutting of copper. SPIE 3097:70–78

Yilbas BS (2004) Laser cutting quality assessment and thermal efficiency analysis. J Mater Process Technol 155–156:2106–2115

Wang Z (1995) Research on some theories and essential techniques of intelligent system for laser process. Doctor Thesis, Huazhong University of Science and Technology (in Chinese)

Xianfeng S, Yao J, Yang W, Jialin Y (2004) Density prediction of selective laser sintering parts based on artificial neural network. Lect Notes Comput Sci 3174:832–840

Hornik K, Stinchcombe M, White H (1989) Multilayer feed forward networks are universal approximators. Neural Netw 2(5):359–366

Acknowledgements

This work was supported by the Beijing Education Ministry under Grants KM200510005013 and the Chinese Nature and Science Foundation (No. 50575005). Editing assistance was provided by American professors Edmund F. Perozzi, and Rhoda E. Perozzi, who are currently teaching at Beijing University of Technology.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jimin, C., Jianhua, Y., Shuai, Z. et al. Parameter optimization of non-vertical laser cutting. Int J Adv Manuf Technol 33, 469–473 (2007). https://doi.org/10.1007/s00170-006-0489-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-006-0489-3