Abstract

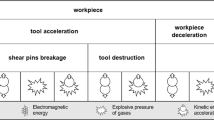

A new electromagnetic quick stop device (EQSD) used for both metal cutting research and teaching is described. This device employs an electromagnet to secure the workpiece while cutting is executed, and then another one to force the workpiece away from the tool instantaneously to obtain the chip sample. In comparison between the conventional quick stop devices and the EQSD, the EQSD is shown to have more safety, longer life, less cost, and less time than the conventional one. The performance of this device was analyzed and tested by a new measuring system. The results showed that the EQSD meets the performance requirement of conventional QSDs.

Similar content being viewed by others

References

Brown RH (1976) A double shear-pin quick-stop device for very rapid disengagement of a cutting tool. Int J Mach Tool Des Res 16:115

Black JT, James CR (1981) The hammer QSD-quick stop device for high speed machining and rubbing. Trans ASME, J Eng Ind 103:13

Hsu TC (1966) A study of the normal and shear stresses on a cutting tool. Trans ASME, J Eng Ind, pp 51

Ellis J, Kirk R, Barrow G (1969) The development of a quick-stop device for metal cutting research. Int J Mach Tool Des Res 9:321

Hastings WF (1957) A new quick-stop device and grid technique for metal cutting research. Annals CIRP 15:109

Spaans C (1971) The fundamentals of three-dimensional chip curl, chip breaking and chip control. Department of Mechanical Engineering Delft University of Technology Report WTHD NO. 24, pp 15

Williams JE, Smart EF, Milner DR (1970) The metallurgy of machining, Part I: basic considerations and the cutting of pure metals. Metallurgia 81:483

Philip PK (1971) Study of the performance characteristics of an explosive quick-stop device for freezing cutting action. Int J Mach Tool Des Res 11:133

Stevenson MG, Oxley PLB (1970) An experimental investigation of the influence of speed and scale on the strain-rate in a zone of intense plastic deformation. Proc, Institute of Mechanical Engineers 184:651

Brown RH, Komanduri R (1973) An investigation of the performance of a quick-stop device for metal cutting studies. Proc, 13th International MTD & R Conference, pp 225

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wu, C., Wang, K. & Tsai, L. A new electromagnetic quick stop device for metal cutting studies. Int J Adv Manuf Technol 29, 853–859 (2006). https://doi.org/10.1007/s00170-005-2608-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-005-2608-y