Abstract

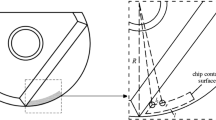

The exit burr generated in the face milling operation at the edge of the workpiece usually requires deburring processes to enhance the level of precision of the parts. This paper is to geometrically understand the formation of the exit burr in the face milling operation on the arbitrary shaped workpiece with multiple feature such as hole, spline, and arc so that we can suggest the cutting conditions and tool path to minimize the burr formation on the given workpiece in the early design stage.

The burr formation mechanism in each type of burr is classified based on the experimental results. A database is developed to store and predict burr formation results. A Windows based program is developed with the algorithm including three steps, i.e., the feature identification, the cutting condition identification, and the analysis on exit burr formation. We can predict which portion of the workpiece would have the exit burr in advance so that we can manage to find a way to minimize the exit burr formation in an actual cutting. Here, the idea of critical burr length is introduced as a criterion in optimization.

Similar content being viewed by others

References

Gillespie LK (1979) Deburring precision miniature parts. Proc Eng 1(4):189–198

Dornfeld DA (1997) Burr minimization in face milling: a geometric approach. ASME 119:170–179

Kim YJ, Lee JY, An YJ (2001) Geometric analysis on the formation mechanism of milling burr on arbitrary feature. Soc CAD/CAM Eng 6(4):222–228

Kim JH, Lee JB, Kim YJ (2002) Development of exit burr identification algorithm on multiple feature and multiple path cutting. KIIE Autumn Scientific Convention, pp 1–15

Han SW, Ko SL (2002) A study on exit burr formation in face milling. KSPE 19(8):55–62

Lee IP, Kim BS (1999) Microsoft Visual Basic 6.0. Sam Yang, Gyeonggi, South Korea

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kim, Y., Kim, J., Ko, S. et al. Development of intelligent system to minimize burr formation in face milling. Int J Adv Manuf Technol 29, 879–884 (2006). https://doi.org/10.1007/s00170-005-2586-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-005-2586-0