Abstract

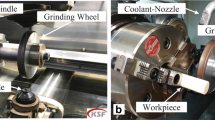

The application of non-conventional truing/dressing (T/D) methods to the recovery of conductive-bond superabrasive wheels has been a matter of great interest in the last years, especially in the case of small-grit size wheels. However, when it comes to the dressing of large-grit size superabrasive wheels, applied in roughing operations, little information is available. The electro discharge dressing (EDD) process can be optimally applied in these cases. In this work a description of the particular mechanisms involved in bonding material removal in the EDD of large-grit size cBN wheels is presented. Indicators are defined in order to quantify the stability and efficiency of the process, and the influence of the main process variables (wheel speed, electrode size and electrical settings) is analyzed. Practical application shows that very important improvements in the grinding performance of the wheels can be obtained by maximizing grit protrusion while avoiding grain loss using this technique .

Similar content being viewed by others

References

Lavine AS, Malkin S, Jen TC (1989) Thermal aspects of grinding with cBN wheels. Ann CIRP 38(1)557–560

Chen X, Rowe WB, Cai R (2002) Precision grinding using cBN wheels. Int J Mach Tools Manuf 42:585–593

Ohmori H, Nakagawa T (1990) Mirror surface grinding of silicon wafers with electrolytic in-process. Ann CIRP 39(1):329–332

Ohmori H, Li W, Makinouchi A, Bandyopadhyay BP (2000) Efficient and precision grinding of small hard and brittle cylindrical parts by the centerless grinding process combined with electro-discharge truing and electrolytic in-process dressing. Int J Mater Process Technol 98:322–327

Lee E (2000) A study of the development of an ultraprecision grinding system for mirror-like grinding. Int J Adv Manuf Technol 16:1–9

Tönshoff HK, Friemuth T (2000) In-process dressing of fine diamond wheels for tool grinding. Int J Precis Eng 24:58–61

Denkena B, Becker JC, Van der Meer M (2004) Potential of electro contact discharge dressing method in truing and sharpening superabrasive grinding wheels. Key Eng Mater 257–258:353–359

Kubo A, Yan J, Narita K (2003) Electro contact discharge dressing of a resin-bonded cBN grinding wheel and its performance. Key Eng Mater 238–239:327–332

Suzuki K, Uematsu T (1997) On-truing/dressing of metal bond grinding wheels by electro-discharge machining. Ann CIRP 36(1):115–118

Iwai M, Ichinose M, Qun HB, Takeuchi K, Uematsu T, Suzuki K (2001) Application of fluid–free EDM to on-machine truing/dressing for superabrasive grinding wheels. Proc Int Symp on Electro Machining XIII, Bilbao, Spain, pp 371–380

Lee E, Ahn S (1999) Precision surface grinding of Mn-Zn ferrite with in-process electro-discharge dressing (IEDD). Int J Mach Tools Manuf 39:1655–1671

Chen DZ, Tian YY (1989) Form dressing of metal-bonded diamond wheel. Proc Int Symp on Electro Machining IX, Nagoya, Japan, pp 18–21

Uematsu T, Suzuki K, Yanase T, Nakagawa T (1992) Recent advancement in on-machine electrodischarge truing for metal bonded diamond wheels. Proc Int Symp on Electro Machining X, Magdeburg, Germany, pp 409–418

Koshky P, Jain VK, Lal GK (1996) Mechanism of material removal rate in electrical discharge diamond grinding. Int J Mach Tools Manuf 36:1173–1185

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sanchez, J., Ortega, N., Lopez de Lacalle, L. et al. Analysis of the electro discharge dressing (EDD) process of large-grit size cBN grinding wheels. Int J Adv Manuf Technol 29, 688–694 (2006). https://doi.org/10.1007/s00170-005-2579-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-005-2579-z