Abstract

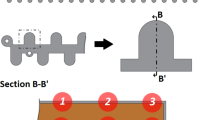

CO2 laser welding of zinc-coated steel sheets in the lap configuration has been a major research effort for the automotive industry for many years. The introduction of a gap between the sheets is one way of solving the zinc gas explosion problem. However, this requires sophisticated clamping devices and spacer materials. A homogeneous gap is therefore difficult to realise in high volume production. This paper describes a simple but useful approach for CO2 laser welding of zinc-coated steel sheets in the lap configuration. By using a gated pulse mode, a seam welding process is developed that allows zinc-coated materials to be welded in a gap-free, overlap configuration. Laser seam welds in the lap configuration were produced in 0.7 mm-thick steel sheet with 7 μm zinc coating on both sides. A number of pulsed CO2 laser welding parameters, including peak power, duty cycle, travel speed, pulse repetition rate, and pulse energy, were identified. Furthermore, the effects of pulsed CO2 laser welding parameters on weldability were also investigated. The study shows that through the proper selection of welding parameters, it is possible to produce visually sound welds where porosity is still unavoidably formed. It was observed that decreasing the welding speed could reduce the porosity within the visually sound welds.

Similar content being viewed by others

References

Riches S (2001) Automotive welding: industrial lasers and their application. Industry Search. Industracom, Australia

Pennington EJ (1987) US Patent No. 4642446

Piane AD, Sartorio F, Cantello M, Ghiringhello G (1987) US Patent No. 4682002

Rito N, Ohta M, Yamada T, Gotoh J, Kitagawa T (1988) US Patent No. 4745257

Imhoff R, Behler K, Gatzweiler W, Beyer E (1988) Laser beam welding in car body making. In: Proceedings of the 6th International Conference on Lasers in Manufacturing, pp 247–258

Akhter R, Steen WM, Cruciani D (1989) Laser welding of zinc-coated steel. In: Proceedings of the 6th International Conference of Lasers in Manufacturing, pp 105–120

Akhter R, Steen WM (1990) The gap model for welding zinc-coated steel sheet. In: Proceedings of the International Conference on Lasers Systems Application in Industry, Torino, Italy, pp 219–236

Graham MP, Hirak DM, Kerr HW, Weckman DC (1994) Nd:YAG laser welding of coated sheet steel. J Laser Appl 6(4):212–222

Raycon Co. (1988) US Patent No. 4873415

Petrick FD (1990) US Patent No. 4916284

General Motors (1991) US Patent No. 5187346

Spies B, Thomas V (1992) US Patent No. 5104032

Berlinger G, Speranza JJ (1987) US Patent 4684779

Ream S (1991) Laser welding of zinc-coated steel. In: Laser applications in materials processing and manufacturing. Society of Manufacturing Engineering (SME), Southfield, MI

Mitsubishi Co. (1993) US Patent 5618452

Ford Motor Co. (1973) US Patent 3881084

General Motors (1992) US Patent 5371337

Heydon J, Nilsson K, Magnusson C (1989) Laser welding of zinc-coated steel. In: Proceedings of the 6th International Conference on Lasers in Manufacturing, pp 93–104

Kennedy SC, Norris IM (1989) Nd-YAG laser welding of bare and galvanized steels. SAE Technical Paper Series 890887, International Congress and Exposition, Detroit, MI

Norris I, Hoult T, Peters C, Wileman P (1992) Material processing with a 3 kW Nd:YAG laser. In: Proceedings of Laser Advanced Materials Processing (LAMP), Nagaoka, Japan

Tzeng YF (1999) Pulsed Nd:YAG laser seam welding of zinc-coated steel. Welding J 78(7):238s–244s

Tolinski M (2001) Laser welding takes a shine to aluminum. Forming Fabr 8(1):1–3

Loredo A, Martin B, Andrzejewski H, Grevey D (2002) Numerical support for laser welding of zinc-coated sheets process development. Appl Surface Sci 195:297–303

Xie J (2002) Dual beam laser welding. Welding J 81(10):223s–230s

Roland-Lee F (2001) Laser welding with dual wavelength technology. Newsletter of Fraunhofer USA, Spring

PRC Corporation (1999) Laser operation manual. Landing, NJ 07850

Steen WM (2001) Laser material processing, 2nd edn. Springer, Berlin Heidelberg New York

Matsunawa A (1994) Defects formation mechanisms in laser welding and their suppression methods. In: Proceeding of ICALEO’94, LIA, Orlando, FL, October 17–20, vol 79, pp 203–209

Katayama S, Kohsaka S, Mizutani M, Nishizawa K, Matsunawa A (1993) Pulse shape optimization for defect prevention in pulsed laser welding of stainless steels. In: Proceeding of ICALEO’93, LIA, Orlando, FL, 24–28 October 1993, vol 77, pp 487–497

Matsunawa A, Kim JD, Seto N, Mizutani M, Katayama S (1999) Dynamics of keyhole and molten pool in laser welding. International Institute of Welding (IIW), Lisbon, IV-751-99, pp 1–9

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yih-fong, T. Gap-free lap welding of zinc-coated steel using pulsed CO2 laser. Int J Adv Manuf Technol 29, 287–295 (2006). https://doi.org/10.1007/s00170-005-2522-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-005-2522-3