Abstract

Prototype injection moulds for plastic parts must face two constraints: be designed and manufactured as quickly as possible and have a short lead time. Moreover, moulds have to evolve in the same way as the part does, to provide either a new functionality or a variant of this part. The current approach is based on a multi component tooling (hybrid rapid tooling) in order to more easily manufacture each component of the mould and to have a greater reactivity to each product evolution.

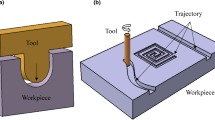

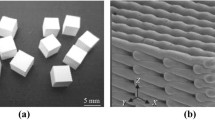

In this paper, we propose a method to manufacture the mould in multi components. This approach is based on process capability criteria (i.e. topological and geometrical criteria). An industrial example is presented. We will focus on the choice between three processes mainly used in hybrid rapid tooling: high speed machining (HSM), electro discharging machining (EDM) and direct metal laser sintering (DMLS).

Similar content being viewed by others

References

Sandvik Coromant (2004) Die & mould making. http://www.coromant.sandvik.com

Bernard A, Taillandier G (1998) Le prototypage rapide. Edition Hermes, pp 14–15

Knirsch J (2003) RSP Tooling – rapid production tooling. International conference on advanced research in virtual and rapid prototyping

Karlsen R, Reitan J (2003) Metal printing – development of a new rapid manufacturing process for metal and ceramic objects. International conference on advanced research in virtual and rapid prototyping

Hur J, Lee K (2002) Hybrid rapid prototyping system using machining and deposition. Comput-Aided Des 34(10):741–754

Zhang H, Wang G, Luo Y, Nakaga T (2001) Rapid hard tooling by plasma spraying for injection molding and sheet metal forming. Thin Solid Films 390:7–12

Wohlers T (2003) Rapid prototyping, tooling and manufacturing state of the industry. Wohlers reports 2003

Syrjälä S (2002) DMLS for injection moulding and die casting applications. Rapid product innovation Oy. Euromold, Dortmund

Raptec (1999) Potential RP process chains for prototype injection moulding and sheet metal forming tools. Project BE-2051. http://www.raptec.org

Hänninen J (2001) DMLS moves from rapid protyping to rapid manufacturing. MPR, http://www.métal-powder.net/sepfeat.htm

Jégou L (2003) Méthod d’aide au choix des procédés en “outillage hybride”. Mémoire de DEA Ecole Centrale de Nantes

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mognol, P., Jégou, L., Rivette, M. et al. High speed milling, electro discharge machining and direct metal laser sintering: A method to optimize these processes in hybrid rapid tooling. Int J Adv Manuf Technol 29, 35–40 (2006). https://doi.org/10.1007/s00170-005-2502-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-005-2502-7