Abstract

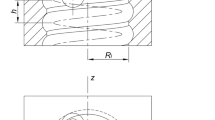

A systematic machining theory and precision method to determine cutter location in a grinding system is presented for rotary burr. First, the helical cutting edge on various kinds of revolving surfaces is built. Then, based on the geometry model of the helical cutting edge, the smooth spiral rake surface with constant normal rake angle and flank surface can been formed during the one-pass grinding process by this method. No interference between the grinding wheel and workpiece happens by the wheel special rotation. The method has the characteristic of detaching the grinding wheel path solution from specified machining conditions. The grinding wheel path is suitable for different NC machine tools through post processing. Meanwhile, a mechanism kinematic model of the NC machine tool is built, and a generalized algorithm for post-processing of multi-axis NC machine tools is presented. This model is applied to arbitrary configuration of NC machine tool, and the motion value for each axis will be generated by the inputting structure and motion parameters of the machine tool. The model, together with the machining method mentioned in this paper, make the calculation and generation of the grinding wheel path simpler and universal. At last, the validity of the method given in the paper is identified by an example of grinding.

Similar content being viewed by others

References

Huran L (1993) The cutting edge of special rotary tool. Tool Technol 27(2):10–12

Changxiu Z (1992) The generating principle of special rotary tool. Tool Technol 25(10):15–19

Chunhua S, Huaming L (2000) Study on general geometric model for spiral surfaces of flute of special revolving tools. Tool Technol 34(3):17–18

Cangxiu Z (1992) The generating theory of the flutes of special revolving tools with constant spiral angle edge. Res Cutting-Tool 22(1):8–15

Feng Y, guanglan X (1999) Study on geometric modeling and machining principle of nose burr. J Jiamusi Univ (Natural science edn) 17(2):110–114

Liu huran (1996) A additional grinding device of numerical control miller. Jixie 1:13–15

Shichang Z (1993) Design and realization of a new type NC tool grinder. Mech Des 2:43–46

Shichang Z (1992) Five-axis numerical control grinder of rotary burr. Mach Auto-Mach Technol 2:25–28

Huran L (1995) The generating theory of special revolving with stagger tooth. Des Manuf Mech 5:33–36

Yonggang W, Huran L Study on the generating principle of special rotary tool and its computer emulation. Tool Technol 28(8):29–33

Yaoxiong H, Yanhong Z, Ji Z (1999) Path generation for NC grinding of rotary cutting tools. J Huazhong Univ Sci Technol 24(4):56–59

Jingyu L, Huaming L (1998) Study on theory of cutting edge modeling and helical groove machining of nose burr. J Harbin Inst Technol 5(4):19–22

Yaoxiong H, Qihe X (2002) Kinematics model and its solution for NC machines of arbitrary configuration. J Mech Eng 38(10):31–36

Huimin Z, Peihong Z (1994) The movement analyzing of machine tool in helical cutting edge machining of burr. Mech Sci Technol 1:70–75

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, C., Yaoxiong, H. & Congxin, L. A manufacturing model of helical groove on rotary burr and a universal post processing method. Int J Adv Manuf Technol 29, 9–16 (2006). https://doi.org/10.1007/s00170-005-2499-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-005-2499-y