Abstract

Sectional multi-point forming (SMPF) technology provides a new solution for forming large-size sheet metal. With this technique, large-size parts of sheet metal can be manufactured on a smaller multi-point forming press. But the force status and deformation of the workpiece are complicated in SMPF; the local severe plastic deformation will be produced easily in the transition region, and strain-hardening will be commonly produced subsequently. The hardening is difficult to eliminate in subsequent processes, which will largely affect the final deformation quality. In this paper, the generation of local severe plastic deformation was discussed; NURBS-based modeling method was used to construct the shape of the assortative region to suppress the defect. Experiments proved that the method is fairly effective. Finally, a plan was suggested to raise further the forming limit of materials and enhance the work efficiency by combining multi-point press forming with assortative region method.

Similar content being viewed by others

References

Li MZ, Nakamura K, Watanabe S (1992) Study of the basic principles (1st report: Research on Multi-point forming for sheet metal). Proc of the Japanese Spring Conf for Technology of Plasticity 519–522 (in Japanese)

Li MZ, Nakamura K (1992) Harmful phenomena in multi-point forming (3rd report: Research on multi-point forming for sheet metal). Proc of the 43rd Japanese Joint Conf for Technology of Plasticity 425–428 (in Japanese)

Li Mingzhe, Liu Yuhong (1999) Multi-point forming: a flexible manufacturing method for a 3D surface sheet. J Mater Process Technol 87:277–280

Hardt DE, Gossard DC (1980) A variable geometry die for sheet metal forming: machine design and control. Proc of the Joint Automatic Control Conference, San Francisco, Aug

Hardt DE et al (1981) Sheet metal forming with discrete die surface. Proc 9th NAMRC 140–144

Chen Jianjun (2005) Sectional multi-point forming technology for large size sheet metal. Int J Adv Manuf Technol 25:935–939

Chen Jianjun (2001) The Study of Multi-Point Forming CAD and Sectional Multi-Point Forming Process. PhD dissertation of Jilin University, China

Yu TC, Zhang LZ (1992) Theory of plastic bending and its application. Science Press, China

Shi FZ (1994) Computer aided geometric design and non-uniform rational B spline (CAGD & NURBS). Beijing Aerospace University Press, China, pp 405–465

Tiller W (1983) Rational B-splines for curves and surfaces representation. IEEE CG & A 9(1):61–69

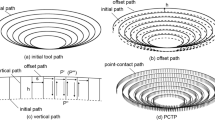

Cai ZY, Li MZ (2002) Multi-point forming of three- dimensional sheet metal and the control of the forming process. Int J Press Vessels Piping 79:289–296

Cai ZY, Li MZ (2001) Optimum path forming technique for sheet metal and its realization in multi-point forming. J Mater Process Technol 110:136–141

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, W., Jia, SS., Zhang, CM. et al. Generation and suppression of local severe plastic deformation in sectional multi-point forming. Int J Adv Manuf Technol 32, 705–710 (2007). https://doi.org/10.1007/s00170-005-0390-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-005-0390-5