Abstract

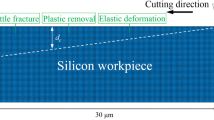

Ductile mode cutting of silicon wafers can be achieved under certain cutting conditions and tool geometry. An experimental investigation of the critical undeformed chip thickness in relation to the tool cutting edge radius for the brittle-ductile transition of chip formation in cutting of silicon wafers is presented in this paper. Experimental tests for cutting of silicon wafers using diamond tools of different cutting edge radii for a range of undeformed chip thickness are conducted on an ultra-precision lathe. Both ductile and brittle mode of chip formation processes are observed in the cutting tests. The results indicate that ductile cutting of silicon can be achieved at certain values of the undeformed chip thickness, which depends on the tool cutting edge radius. It is found that in cutting of silicon wafers with a certain tool cutting edge radius there is a critical value of undeformed chip thickness beyond which the chip formation changes from ductile mode to brittle mode. The ductile-brittle transition of chip formation varies with the tool cutting edge radius. Within the range of cutting conditions in the present study, it has also been found that the larger the cutting edge radius, the larger the critical undeformed chip thickness for the ductile-brittle transition in the chip formation.

Similar content being viewed by others

References

John CS (1975) The brittle-to-ductile transition in pre-cleaved silicon single crystals. Philos Mag 32:1193–1212

Samuels J, Roberts SG, Hirsch PB (1988) The brittle-to-ductile transition in silicon. Mater Sci Eng A 105/106:39–46

Ferney BD, Hsia KJ (1999) The influence of multiple slip systems on the brittle-ductile transition in silicon. Mater Sci Eng A 272:422–430

Koshimizu S, Otsuka J (1998) Microindentation tests of single-crystal silicon-microdeformation behavior and measurement of ductile to brittle transition. J Japan Soc Prec Eng 64:1643–1647

Yan J, Yoshino M, Kuriagawa T, Shirakashi T, Syoji K, Komanduri R (2001) On the ductile machining of silicon for micro electro-mechanical system (MEMS), opto-electronic and optical applications. Mater Sci Eng A 297:230–234

Hung NP, Fu YQ (2000) Effect of crystalline orientation in the ductile-regime machining of silicon. Int J Adv Manu Tech 16:871–876

Blackley WS, Scattergood RO (1994) Chip topography for ductile-regime machining of germanium. ASME J Eng Ind 116:263–266

Fang FZ, Venkatesh VC (1998) Diamond cutting of silicon with nanometric finish. Annals CIRP 47:45–49

Liu K, Li XP, Liang SY. The mechanism of ductile chip formation in cutting of brittle materials. Inter J Adv Manu Tech (in press)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, K., Li, X.P., Rahman, M. et al. A study of the effect of tool cutting edge radius on ductile cutting of silicon wafers. Int J Adv Manuf Technol 32, 631–637 (2007). https://doi.org/10.1007/s00170-005-0364-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-005-0364-7