Abstract

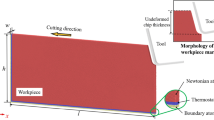

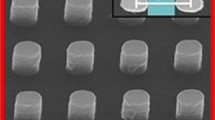

For ductile mode cutting of brittle materials, such as silicon wafers, the undeformed chip thickness has to be smaller than the tool edge radius. In practical application, for high production rate, the undeformed chip thickness is expected to be as large as possible. Therefore, the tool edge radius is expected to be as large as possible. In this study, the upper bound of the tool edge radius is investigated through cutting experiments.

Similar content being viewed by others

References

Blake PN, Scattergood RO (1990) Ductile-Regime Machining of Germanium and Silicon. J Am Ceram Soc 73 (4):949–957

Nakasuji T, Kodera S, Hara S, Matsunaga H, Ikawa N, Shimada S (1990) Diamond turning of brittle materials for optical components. Ann CIRP 39 (1):89–92

Puttick KE, Whitmore LC, Chao CL, Gee AE (1994) Transmission electron microscopy of nanomachined silicon crystals. Philosoph Mag A 69(1):91–103

Lucca DA, Chou P, Hocken RJ (1998) Effect of tool edge geometry on the nanometric cutting of Ge. Ann CIRP 47 (1):475–478

Leung TP, Lee WB, Lu XM (1998) Diamond turning of silicon substrates in ductile-regime. J Mater Process Technol 73:42–48

Chao CL, Ma KJ, Liu DS, Bai CY, Shy TL (2002) Ductile behavior in single-point diamond-turning of single-crystal silicon. J Mater Process Technol 127:187–190

Liu K, Li XP (2001) Ductile cutting of tungsten carbide. J Mater Process Technol 113(1–3):348–354

Liu K, Li XP, Rahman M, Neo KS, Chan CC, Liu XD (in press) A study of the effect of tool cutting edge radius on ductile cutting of silicon wafers. Int J Adv Manuf Tech

Blackley WS, Scattergood RO (1994) Chip topography for ductile-regime machining of germanium. ASME Trans, J Eng Ind 116:263–266

Fang FZ, Venkatesh VC (1998) Diamond cutting of silicon with nanometric finish. Ann CIRP 47 (1):45–49

Shibata T, Fujii S, Makino E, Ikeda M (1996) Ductile-regime turning mechanism of single-crystal silicon. Prec Eng 18:129–137

Liu K, Li XP (2001) Modeling of ductile cutting of tungsten carbide. Trans NAMRI/SME XXIX:251–258

Li XP, Rahman M, Liu K, Neo KS, Chan CC (2003) Nano-precision measurement of diamond tool edge radius for wafer fabrication. J Mater Process Technol 140:358–362

Liu K, Li XP, Liang SY (in press) The mechanism of ductile chip formation in cutting of brittle materials. Int J Adv Manuf Technol

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Arefin, S., Li, X.P., Rahman, M. et al. The upper bound of tool edge radius for nanoscale ductile mode cutting of silicon wafer. Int J Adv Manuf Technol 31, 655–662 (2007). https://doi.org/10.1007/s00170-005-0245-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-005-0245-0