Abstract

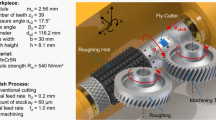

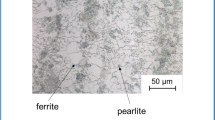

Two PVD coated powder metallurgy high speed steel (PM-HSS) gear cutters were investigated when machining helical gears made from AISI 19MnCr5 steel with hardness between 140 and 180 HV. Machining trials were carried out with gear cutters coated with TiAlN (nano layers) and TiN (mono layer). Crater and flank wears were measured and analysed after all the machining trials. Analyses of the worn tools show that the TiAlN coated gear cutter performed better than the TiN coated gear cutter. This can be attributed to its nano layers and the higher hardness of the TiAlN coating. The dominant tool wear mechanisms were adhesion, abrasion, delaminating of the coating layer and chipping of the cutting edge.

Similar content being viewed by others

Abbreviations

- CVD:

-

Chemical vapour deposition

- CNC:

-

Computer numerical control

- doc:

-

Depth of cut (mm)

- EDX:

-

Energy dispersive x-ray

- f :

-

Feed rate (mm/rev)

- H a :

-

Hardness of the abrasive grains (kgf/mm2)

- H a/H s :

-

Hardness ratio

- H s :

-

Hardness of the surface (kgf/mm2)

- HV:

-

Vickers hardness (kgf/mm2, where kgf/mm2=9.807 MPa)

- PCBN:

-

Polycrystalline cubic boron nitride

- PCD:

-

Polycrystalline compact diamond

- PM-HSS:

-

Powder metallurgy – high speed steel

- PVD:

-

Physical vapour deposition

- SEM:

-

Scanning electron microscope

- VB max :

-

Maximum flank wear (mm)

- v c :

-

Cutting speed (m/min)

References

Jost PH (1990) Tribology-origin and future. Wear 136:1–17

Trent EM (1988a) Metal cutting and the tribology of seizure: I seizure in metal cutting. Wear 128:29–45

Trent EM (1988b) Metal cutting and the tribology of seizure: II movement of work material over the tool in metal cutting. Wear 128:47–64

Trent EM (1988c) Metal cutting and the tribology of seizure: III temperatures in metal cutting. Wear 128:65–81

König W, Neises A (1993) Wear mechanisms of ultrahard, non-metallic cutting materials. Wear 162–164:13–21

Dolinsek S, Sustarsic B, Kopac J (2001) Wear mechanisms of cutting tools in high-speed cutting processes. Wear 250:349–356

Kopac J, Sokovic M, Dolinsek S (2001) Tribology of coated tools in conventional and HSC machining. J Mater Process Technol 118:377–384

Poulachon G, Moisan A, Jawahir IS (2001) Tool-wear mechanisms in hard turning with polycrystalline cubic boron nitride tools. Wear 250:576–586

Liu ZQ, AI X, Zhang H, Wang ZT, Wan Y (2002) Wear patterns and mechanisms of cutting tools in high-speed face milling. J Mater Process Technol 129:222–226

Zhang S, Zhu W (1993) TiN coating of tool steels: a review. J Mater Process Technol 39:165–177

Chen WC, Tsao CC (1999) Cutting performance of different coated twist drills. J Mater Process Technol 88:203–207

Balzers (2004) Balzers coating guide. Balzers, Liechtenstein

Trent EM, Wright PK (2000) Metal cutting, 3rd edn. Butterworth Heinemann, Boston, p 446

Hutchings IM (1995) Tribology: friction and wear of engineering materials. CRC Press, England, UK

Williams JA (1995) Engineering tribology. Oxford University Press, UK

Zum Gahr KH (1987) Microstructure and wear of materials. Elsevier, Amsterdam

Santos SC, Sales WF, Silva FJ, Franco SD, Silva MB (2002) Tribological characterisation of PVD coatings for cutting tools. Surf Coat Technol 184:141–148

Acknowledgements

The authors would like to thank FA Powertrain Ltd for providing equipment and materials for the experimental tests and also to CAPES (Coordenação de Aperfeiçoamento de Pessoal de Ensino Superior, Processo No. PDE 0333–04–2) for their assistance in developing this project.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

dos Santos, J.A.B.O., Sales, W.F., Santos, S.C. et al. Tribological evaluation of TiN and TiAlN coated PM-HSS gear cutter when machining 19MnCr5 steel. Int J Adv Manuf Technol 31, 629–637 (2007). https://doi.org/10.1007/s00170-005-0242-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-005-0242-3