Abstract

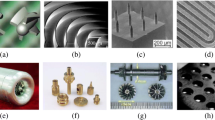

This paper discusses the microfabrication of micromilling tools using wire electrodischarge grinding (WEDG) and focused ion beam (FIB) sputtering. The tool blank of tungsten carbide was produced by WEDG and the cutting edges were formed by FIB sputtering. Using these two complementary processes micromilling tools were fabricated with submicrometer accuracy and nanometric levelled surface finish. The fabricated microtools were used to mill microchannels on polymer. The fabricated microtool and microchannels were inspected using an optical surface profiler, atomic force microscope (AFM) and scanning electron microscope (SEM). The length of the microchannels ranges from 0.5 mm to 2 mm. The maximum trench depth was 5μm. The widths of the channels were about 10–20% larger than the tool diameter when milling without and with lubrication, respectively. An average surface finish of 80 nm was achieved.

Similar content being viewed by others

References

Sigmund P (1981) Sputtering by particle bombardment I. In: Behrisch R (ed) Topics in applied physics. Springer, Berlin Heidelberg New York

Vasile MJ, Xie J, Nasar R (1999) Depth control of focused ion beam milling from numerical model of the sputter process. J Vac Sci Technol B 17(6):3085–3090

Ali MY, Hung NP, Ngoi BKA, Yuan S (2003) Sidewall surface roughness of sputtered silicon, part i: surface modeling. Surf Eng 19(2):97–103

Ali MY, Hung NP, Ngoi BKA, Yuan S (2003) Sidewall surface roughness of sputtered silicon, part ii: model verification. Surf Eng 19(2):104–108

Hung NP, Fu YQ, Ali MY (2002) Focused-ion-beam machining of silicon. J Mater Process Technol 127(2):256–260

Ali MY, Hung NP (2001) Surface roughness of sputtered silicon, part i: surface modeling. Mater Manuf Process 16(3):297–313

Ali MY, Hung NP (2001) Surface roughness of sputtered silicon, part ii: model verification. Mater Manuf Process 16(3):315–329

Hung NP, Ali MY, Fu YQ, Ong NS, Tay ML (2001) Surface integrity and removal rate of sputtered silicon. Mach Sci Technol 5(2):239–254

Vasile MJ (1994) Microfabrication by ion milling: the lathe technique. J Vac Sci Technol B 12(4):2388–2393

Friedrich CR, Vasile MJ (1996) Development of the micromilling process for high-aspect-ratio microstructures. J Microelectromech S 5(1):33–38

Friedrich CR, Vasile MJ (1996) The micromilling process for high-aspect-ratio microstructures. J Microsyst Technol 2(3):144–148

Masuzawa T, Fujino M (1990) A process for manufacturing very fine pin tools. Proceedings of the international manufacturing technology conference, Chicago, SME, MS90–307

Chen R-H, Chang C-C, Cheng C-M (2005) Fabricating micromold insert using a novel process. Int J Adv Manuf Techonol 25(7–8):678–684

Friedrich CR, Kulkarni VP (2004) Effect of workpiece springback on micromilling forces. J Microsyst Technol 10(6–7):472–477

Wells WR (1998) End milling with high speed steel for the future and now. SME technical paper, MR88-252

Bhushan B (1999) Principles and applications of tribology. Wiley, New York

Green RE (ed) (1996) Machiner’s handbook. Industrial, New York

Orloff J (ed) (1997) Handbook of charged particle optics. CRC Press, New York

Prewett PD, Mair GLR (1991) Focused ion beams from liquid metal ion sources. Wiley, New York

Acknowledgement

The kind help from the Precision Engineering and Nanotechnology Centre at Nanyang Technological University, Singapore has been much appreciated.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ali, M.Y., Ong, A.S. Fabricating micromilling tool using wire electrodischarge grinding and focused ion beam sputtering. Int J Adv Manuf Technol 31, 501–508 (2006). https://doi.org/10.1007/s00170-005-0220-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-005-0220-9