Abstract

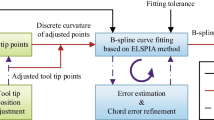

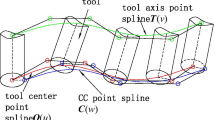

Aiming at the special requirements of a shoe last high-speed machining process and the large dataset which could be gained by the reverse engineering technique, this paper analyzes the conventional tool-offset methods and presents a B-spline tool-offset model. A simple vector-analyzed algorithm to smooth the tool-offset curve in which there are local strange points is proposed, and then the second tool-offsetting, which obtains the fine data of the machining tool’s center points, is directly processed. To reduce the error from tool offsetting of the C2 continuity curve, this paper gains a smoother curve after processing via the edge points joint algorithm, which effectively solved the overcut or undercut problems in the high-speed machining of the spline curve.

Similar content being viewed by others

References

Wang X, Shi D, Luo D, Qian J, Zhong X (2000) Research on machining last by numerical controlled last carving machine [J]. J Chongqing University (Natural Science Ed) 23(4):30–32

Chase TA, Cleary J, Luo RC (1995) Custom shoe last fabrication through CNC milling. In: Proceedings of the IEEE International Conference on Industrial Electronics, Control, Instrumentation and Automation (IECON’95), Orlando, Florida, November 1995, vol 2, pp 1626–1630

Jimeno AM, Chamizo JMG, Salas F (2001) Shoe last machining using virtual digitising. Int J Adv Manuf Technol 17(10):744–750

Weir DJ, Milroy MJ, Bradley C, Vickers GW (1996) Reverse engineering physical models employing wrap-around B-spline surfaces and quadrics. Proc Inst Mech Eng–B J Eng Manuf 210(B2):147–157

Lartigue C, Thiebaut F, Maekawa T (2001) CNC tool path in terms of B-spline curves. Comput Aided Design 33(4):307–319

Luo Q, Chen D, Yang A (1996) An algorithm of cutting tool radius compensation [J]. J Wuhan Transportation University 20(2):214–218

Shi X, Zhao W, Di S (1998) Research on cutter radius compensation for NC system [J]. Modular Machine Tool & Automatic Manufacturing Technique (11):15–19

Wu Z, Qin P (2001) Numerical control machine [M]. Shanghai Scientific & Technical Publishers, Shanghai

Zhao CS, Mohr R (1995) Epipolar parameterization for reconstructing a 3D rigid curve. In: Proceedings of the International Symposium on Computer Vision (ISCV’95), Coral Gables, Florida, November 1995, vol 4, pp 67–72

Lee S, Wolberg G, Sung SY (1997) Scattered data interpolation with multilevel B-splines. IEEE Trans Vis Comput Graph 3(3):228–244

Jiang D, Liu Z (1994) B-spline approximation of offset curves. Chin J CAD & CG 6(2):90–94

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hu, J., Shen, H., Zeng, S. et al. B-spline tool offset of a free-form curve in the shoe last high-speed machining CNC system. Int J Adv Manuf Technol 30, 864–869 (2006). https://doi.org/10.1007/s00170-005-0129-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-005-0129-3