Abstract

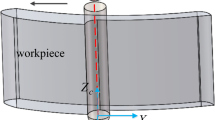

In this paper, machining a ruled surface with a conical tool is discussed. The main goal of our method (the spatial tangent points shift method) is to minimize the error between the given surface and the machined surface. A three-step-optimization is applied. In each step, the cutting tool is tangential to two guiding rails. The guiding rails can be located anywhere within the ruled surface. The first step is to initialize the tool position and find the point with the biggest deviation; the second step tries to minimize the surface error by moving the guiding rails towards the point with the largest deviation along the ruling line, which reduces the surface error to nearly half of its original value; the third step is to shift the tool position along the feed direction to further reduce the error between the given surface and the machined surface. We test the effect of various tool parameters on our method, and we compare our method to other methods of milling with a conical tool. Finally, we used our method to machine a test part and the accuracy of the assessment was verified experimentally.

Similar content being viewed by others

References

Monies F, Redonnet J-M, Rubio W, Lagarrigue P (2000) Improved position of a conical mill for machining ruled surfaces: application to turbine blades. J Eng Manuf 214(B):625–634

Monies F, Rubio W, Redonnet J-M, Lagarrigue P (2001) Comparative study of interference caused by different position settings of a conical milling cutter on a ruled surface. J Eng Manuf 215(9):1305–1317

Monies F, Felices JN, Rubio W, Redonnet J-M, Lagarrigue P (2002) Five-axis NC milling of ruled surfaces: optimal geometry of a conical tool. Int J Prod Res 40(12):2901–2922

Stute G, Storr A, Sielaff W (1979) NC programming of ruled surfaces for five-axis-machining. Ann CIRP 28(1):267–271

Bedi S, Mann S, Menzel C (2003) Flank milling with flat end cutters. Comput Aided Design 35:293–300

Liu X (1995) Five-axis NC cylindrical milling of sculptured surfaces. Comput Aided Design 27(12):887–894

Mann S, Bedi S (2002) Generalization of the imprint method to general surfaces of revolution for NC machining. Comput Aided Design 34(5):373–378

Li C, Mann S, Bedi S (2005) Error measurements for flank milling. Comput Aided Design (submitted)

Li C (2004) Flank milling of ruled surfaces with conical tools. Master’s thesis, University of Waterloo, Ontario, Canada

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, C., Bedi, S. & Mann, S. Flank milling of a ruled surface with conical tools—an optimization approach. Int J Adv Manuf Technol 29, 1115–1124 (2006). https://doi.org/10.1007/s00170-005-0002-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-005-0002-4