Abstract

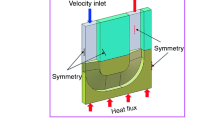

The main purpose of this study is to develop a cylindrical flow cooling method in an induction heating system that is capable of producing the nanofluid. The system consists of a high frequency induction heating system, vacuum system, temperature control system, and a cylindrical curtain collector. The raw material Zn is evaporated by the high frequency induction heating system. The gas phase Zn is condensed and collected by a water cylindrical curtain collector. During the process, the gas phase Zn is oxidized. The ZnO nanoparticles were collected and suspended in de-ionized water. Through transmission electron microscopy (TEM), field emission scanning electron microscope (FESEM), X-ray diffraction (XRD) and particle size analyzer (PSA), a set of applicable parameters size can be obtained. Results show that the lower the collecting liquid temperature and the shorter the collecting distance, the smaller the nanoparticle size obtained. An aspect of UV/V is absorbency, the produced ZnO nanofluid absorbed UV when the wavelength is 360 nm to 380 nm.

Similar content being viewed by others

References

Richard PF (1959) There is plenty of room at the bottom. Annual meeting of the American Physical Society, 29 December 1959

Kubo R (1962) Electrical properties of metallic fine particles I. J Phy Soc Japan 17(6):975–986

Roco MC, Williams RS, Alivisatos P (1999) Vision for nanotechnology R&D in the next decade. IWGN Workshop Report

Jang HD, Kim SK, Kim SJ (2001) Effect of particle size and phase composition of titanium dioxide nanoparticles on the photocatalytic properties. J Nano Res 3(2):141–147

Garca N, Nieto-Vesperinas M, Rohrer H (1998) Nanoscale science and technology. Kluwer, Boston

Su PS (1989) Technology about supermicroparticle materials. Fuhan, Taipei,

Chen SL (1995) Application of high frequency induction. Chuan-Wa, Taipei,

Cui ZL, Dong LF, Hao CC (2000) Microstructure and magnetic property of nano-Fe particles prepared by hydrogen arc plasma. Mater Sci Eng 286(1):205–207

Chuang WF (1997) Theory and application of ultrafine particles. Fuhan, Taipei,

Patel MR, Barrufet MA, Eubank PT, DiBitonto DD (1989) Theoretical models of the electrical discharge machining process II. The anode erosion model. J Appl Phys 66(9):4104–4111

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tsung, TT., Lo, CH., Jwo, CS. et al. A novel nanofluid manufacturing process using a cylindrical flow cooling method in an induction heating system. Int J Adv Manuf Technol 29, 99–104 (2006). https://doi.org/10.1007/s00170-004-2500-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-004-2500-1