Abstract

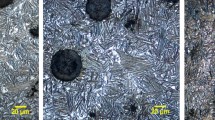

In this study, the machinability of standard GGG40 nodular cast iron by WEDM using different parameters (machining voltage, current, wire speed, and pulse duration) was investigated. From the results, the increase in surface roughness and cutting rate clearly follows the trend indicated with increasing discharge energy as a result of an increase of current and pulseon time, because the increased discharge energy will produce larger and deeper discharge craters. Three zones were identified in rough regimes of machining for all samples: decarburized layer, heat affected layer, and bulk metal. High machining efficiency can be obtained when the proper electrical parameters are selected, but whether high energy or the low energy is used, a coarse surface is always obtained. The variation of surface roughness and cutting rate with machining parameters is mathe-matically modeled by using the regression analysis method.

Similar content being viewed by others

References

Ghani AK, Choudhury I, Husni A (2002) Study of tool life, surface roughness and vibration in machining nodular cast iron with ceramic tool. J Mater Process Technol 127:17–22

Rozenek M, Kozak J, Dabrowski L, Lubkowski K (2001) Electrical discharge machining characteristics of metal matrix composites. J Mater Process Technol 109: 367–370

Guo ZN, Wang X, Huang ZG, Yue TM (2002) Experimental investigation into shapping particle-reinforced material by WEDM-HS. J Mater Process Technol 129:56–59

Prohaszka J, Mamails AG, Vaxevanidis NM (1997) The effect of electrode material on machinability in wire electro-discharge machining. J Mater Process Technol 69:233–237

Snoeys R, Staelens F, Dekeyser W (1986) Curent trends in non-conventional material removal processes. Ann CIRP 35(2):467

Mamails AG, Vaxevanidis NM, Karafillis AP (1990) Surface integrity and formability of steel sheet. Fortschritt-berichte VDI-Z, vol 2, Nr. 197, VDI Verlag, Düsseldorf, p 219

Luo YF (1999) Rupture failure and mechanical strength of the electrode wire used in wire EDM. J Mater Process Technol 94:208–215

Özdemir N, Özek C, Orhan N (2003) Investigation on machinability of nodular cast iron by WEDM. 3rd International Advanced Technologies Symposium, pp 1–6

Tosun N, Cogun C (2003) Analysis of wire erosion and workpiece surface roughness in WEDM. Proc Instn Mech Eng Part B: J Eng Manuf 217(5):633–642

Tosun N (2003) The effect of the cutting parameters on performance of WEDM. KSME Int J 17(6):816–824

Tosun N, Cogun C, Inan A (2003) The effect of cutting parameters on workpiece surface roughness in wire EDM. Mach Sci Technol 7(2):209–219

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Özdemir, N., Özek, C. An investigation on machinability of nodular cast iron by WEDM. Int J Adv Manuf Technol 28, 869–872 (2006). https://doi.org/10.1007/s00170-004-2446-3

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/s00170-004-2446-3