Abstract

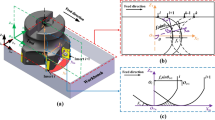

In this study, we aimed to optimize cutting parameters to minimize surface roughness in up-face milling. An experimental system method has been used to analyze the evolution of surface roughness in connection with cutting parameters, and to develop mathematical models for roughness and optimal cutting parameter calculation. Roughness results show that lower cutting speeds give poor surface quality. This is due to the formation of a built-up edge. On the other hand, higher cutting speeds result in more roughness due to vibrations. So, an optimal value of cutting speed must be used to minimize roughness. We found good correlation in experimental values of roughness .

Similar content being viewed by others

References

Bouzid Sai W, Ben Salah N, Lebrun JL (2001) Influence of machining by finishing milling on surface characteristics. Int J Mach Tools Manuf 41:443–450

Ben Salah N, Bouzid Sai W (1997) Modification by mechanical treatments of a duplex stainless steel and its influence on localized corrosion in sea water. Microstructural Sci 25:107–112

Imai T, Katayama S (1990) Effect of tool materials on surface machined roughness and cutting force of low carbon resulfurized free machining steels. ISIJ Int 30:331–337

Ramakrishna Rao PK, Shunmugam MS (1987) Investigations into surface topography, microhardness and residual stress in boring trepanning association machining. Wear 119:89–101

Simon S, Hector LG, Richmond O (1998) Tool topographies for controlling friction and wear in metal forming processes. J Tribology 120:517–524

Zhang GM, Kapoor SG (1991) Dynamics of machined surface, part 2: construction of surface topography. J Eng Indust 113:145–153

Ben Salah N, Chaouachi MA, Chellouf A (1996) Role of surface finishing on pitting corrosion in sea water of a duplex stainless steel. J Mater Eng Perform 5:220–225

Goupy J (1989) La méthode des plans d’expériences. Dunod, Paris (in French)

Taguchi G, Konishi S (1987) Orthogonal arrays and linear graphs. ASI Press, Dearborn, MI

Pilvin P (1988) Identification des paramètres de modèles de comportement, In: Proceedings of MECAMAT, Besan, 30 August–1 September, pp 155–164 (in French)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Saï, K., Bouzid, W. Roughness modeling in up-face milling. Int J Adv Manuf Technol 26, 324–329 (2005). https://doi.org/10.1007/s00170-004-2305-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-004-2305-2