Abstract

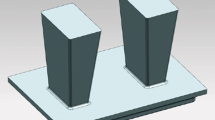

Rapid prototyping (RP) combined with a gravity casting process can provide a suitable substitute with steel tool die casting for prototyping metal casting. Due to differences between die casting and gravity casting, there are several drawbacks in RP simulated die casting. This paper is concerned with the development of a new plaster die casting process that combines pressurization and vibration for prototyping of die castings, and with a plaster die casting machine that has a structure similar to that of a die casting machine. The machine utilizes an oil cylinder for pressurization and a magnetic actuator for vibration. A rapid prototyped pattern is made by the laminated object manufacturing (LOM) process to prepare a plaster mold. In the process, a plunger in the developed machine simultaneously pressurizes and vibrates the molten metal to fill the plaster mold completely and to facilitate the creation of nuclei in the molten metal, respectively. The developed machine has produced a prototype of an end clutch cover with remarkable improvement in mechanical properties.

Similar content being viewed by others

References

Ashley S (1995) Rapid prototyping is coming of age. Mech Eng 117(7):62–68

Kochan A (1997) Rapid prototyping trends. Rapid Prototyp J 3(4):150–152

Jacobs PF (1996) Stereolithography and other RP&M technology from rapid prototyping to rapid tooling. ASME Press, New York

Lee CW, Chua CK, Cheah CM, Tan LH, Feng C (2004) Rapid investment casting: direct and indirect approaches via fused deposition modeling. Int J Adv Manuf Technol 23:93–101

Shan Z, Yan Y, Zhang R, Q Lu, Guan L (2003) Rapid manufacture of metal tooling by rapid prototyping. Int J Adv Manuf Technol 21:469–475

Wohlers TT (2001) Rapid prototyping & tooling state of the industry. Wohlers report, Wohlers Associate, Fort Collins, Colorado, USA

Karapatis NP, Griethuysen JPS, Glardon R (1997) Direct rapid tooling: a review of current research. Rapid Prototyp J 4(2):77–89

Warner MC, Renaud J (1995) Rapid prototyping simulated die casting: lower prototype tooling costs and faster product development are benefits that outweigh limitations. NADCA 18th international die casting congress and exposition, Indianapolis, MN

Warner MC, Renaud J (1996) Rapid prototype simulated die casting. The proceedings of the rapid prototyping & manufacturing conference 1996, Dearborn, MI, USA

Freedman AH, Wallace JF (1957) The influence of vibration on solidifying metals. Trans AFS 65:578–589

Garlick RG, Wallace JF (1959) Grain refinement of solidifying metals by vibration. Trans AFS 67:366–374

Sankaran R, Sreenivasa KS (1970) Effect of low-frequency vibration of solidification, structure and mechanical properties of Al-Cu Alloys. Trans AFS 78:180–186

Ivanic LJ, Kocovski B, Kilibarda Z (1996) The dependence of cast structure on geometric shape, vibration condition and thermophysical properties of mold. Bull Mater Sci 19(1):161–164

Kim KD, Yang DY, Park TK (1999) Design and development of trial die casting process by using rapid prototyping. The proceedings of rapid prototyping & manufacturing conference 1999, Illinois, USA

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kim, K.D., Yang, D.Y. & Jeong, J.H. Plaster casting process for prototyping of die casting based on rapid tooling. Int J Adv Manuf Technol 28, 923–929 (2006). https://doi.org/10.1007/s00170-004-2291-4

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/s00170-004-2291-4