Abstract

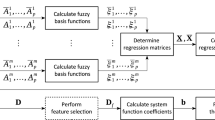

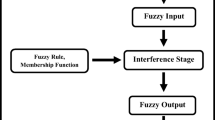

In this paper, an integrated decision support system is developed, which employs fuzzy techniques to assist decision-makers in choosing an optimal solution from alternative manufacturing options in an uncertain environment. The integrated approach incorporates different justification methods (e.g., strategic, economic, and analytic evaluations) for assessing tangible benefits, like cost, and intangible benefits, like quality, of different alternatives by a fuzzy multi-criteria decision-making method. As an illustrative example, selection of different advanced manufacturing technologies has been demonstrated by using the proposed methodology. The proposed concept will greatly reduce conflicts between tangible and intangible factors, and enhance the process of identification, interpretation, and diagnosis of the value of complex manufacturing and engineering systems.

Similar content being viewed by others

References

Zadeh LA (1975) The concepts of linguistic variable and its application to approximate reasoning, Inf Sci 8(1):199–249

Liang GS, Wang MJ (1991) A fuzzy multi-criteria decision making method for facility site selection. Int J Prod Res 29(11):2313–2330

Prabhu TR, Vizayakumar K (1996) Fuzzy hierarchical decision making method (FHDM): A methodology for technology choice. Int J Comput Appl Technol 9(5):322–329

Kuei CH, Lin C, Madu CN (1994) A strategic decision model for the selection of advanced technology. Int J Prod Res 32(9):2117–2130

Willis RG, Sullivan KH (1984) CIM in perspective: costs, benefits, timing, payback periods are outlined. Ind Eng 4(2):28–35

Attaran M (1989) The automated factory: justification and implementation. Bus Horiz 32(3):80–85

Hayes RH, Jaikumar R (1991) Requirements for successful implementation of new manufacturing technologies, J Eng Technol Manage 7(2):169–175

Poo AN (1990) A case for further automation. Mirror, January, pp 10–12

Meredith JR (1987) Implementation new manufacturing technologies: managerial lessons over the FMS life cycle. Interface 17(6):51–62

Stainer A, Ghobadian A, Liu J, Stainer L (1996) Strategic investment appraisal for advanced manufacturing technology. Int J Mater Prod Technol 11:76–88

Ordoobadi SM, Mulvaney NJ (2001) Development of a justification tool for advanced manufacturing technologies: system-wide benefits value analysis. J Eng Technol Manage 18(2):157–184

T Hill (1989) Manufacturing strategy: text and cases. Irwin, New York

Chan FTS, Chan MH, Lau H, Ip RWL (2001) Investment appraisal techniques for advanced manufacturing technology (AMT): a literature review. Int J Manuf Technol Manage 21(1):35–47

Koenig DT (1990) Computer integrated manufacturing: theory and practice. Hemi-sphere, New York

Fotsch RJ (1984) Machine tool justification policies: their effect on productivity and profitability. J Manuf Systems 3(2):169–195

Rosenthal S (1984) A survey of factory automation in the US. Oper Manage Rev, Winter, pp 41–48

Chui YC, Chan SP (1994) Fuzzy cash flow analysis using present worth criterion. Eng Economist 39(2):113–138

Kaplan RS (1984) Yesterday’s accounting undermines production. Harvard Bus Rev 62(4):95–101

Curtis DA (1987) An heuristic to evaluate investments for improved economies of scope in manufacturing. J Manuf Syst 6(4):325–327

Toone R (1994) Manufacturing success – how to manage your competitive edge. Prentice-Hall, New York

Chen IJ, Small MH (1994) Implementing advanced manufacturing technology: an integrated planning model. Manage Sci 22(1):91–103

Meredith JR, Suresh NC (1986) Justification techniques for advanced manufacturing technologies. Int J Prod Res 24(5):1043–1057

Sullivan WG (1986) Models IES can use to include strategic, nonmonetary factors in automation decisions. Ind Eng 18(2):42–50

Saaty TL (1990) The analytic hierarchy process. McGraw-Hill, New York

Zahedi F (1986) The analytic hierarchy process – a survey of the method and its applications. Interface 16(4):96–108

Krinsky I, Miltenburg J (1991) Alternate method for the justification of advanced manufacturing technologies. Int J Prod Res 29(5):997–1015

Persentili E, Alptekin SE (2000) Product flexibility in selecting manufacturing planning and control strategy. Int J Prod Res 38(9):2011–2021

Efstathiadesa A, Tassoub S, Antoniouc A (2002) Strategic planning, transfer and implementation of advanced manufacturing technologies (AMT)./ Technovation 22(4):201–212

Wang MJ, Liang GS (1995) Benefit/cost analysis using fuzzy concept. Eng Economist 40(4):359–376

Czogala E (1990) Multicriteria decision making by mean of fuzzy and probabilistic sets. Fuzzy Sets Syst 36:235–244

Leung Y (1980) A fuzzy sets procedure for project selection. In: Wang PP, Chang SK, eds. Fuzzy sets, theory and applications to policy analysis and information systems. Plenum, New York, pp 329–341

Ward TL (1989) Fuzzy discounted cash flow analysis. In: Evans GW, Wilhelm MR, Karwowski W, eds. Applications of fuzzy set methodologies in industrial engineering. Elsevier, Amsterdam, pp 91–102

Buckley JJ (1987) The fuzzy mathematics of finance. Fuzzy Sets Syst 21:257–273

Porter ME (1980) Competitive strategy. Free Press, New York

Hayes RH, Wheelwright SC (1984) Restoring our competitive edge: competing through manufacturing. Wiley, New York

Kaufmann A, Gupta MM (1988) Fuzzy mathematical model in engineering and management science. Elsevier, Amsterdam

Sohal AS, Schroder R, Uliana EO, Maguire W (2001) Adoption of AMT by South African manufacturers. Integr Manuf Syst 12(1):15–34

Orr S (2002) A comparison of AMT strategies in the USA, South Africa and Germany. Int J Manuf Technol Manage 4(6):441–454

Saleh B, Hacker M, Randhawa S (2001) Factors in capital decisions involving advanced manufacturing technologies. Int J Oper Prod Manage 21(10):1265–1288

Verter V, Dasci A (2002) The plant location and flexible technology acquisition problem. Eur J Oper Res 136(2):366–382

Bokhorst JAC, Slomp J, Suresh NC (2002) An integrated model for part-operation allocation and investments in CNC technology. Int Prod Econ, 75(3):267–285

MacDougall SL, Pike RH (2003) Consider your options: changes to strategic value during implementation of advanced manufacturing technology. Omega 31(1):1–15

Yusuff RM, Yee KP, Hashmi MSJ (2001) A preliminary study on the potential use of the analytical hierarchical process (AHP) to predict advanced manufacturing technology (AMT) implementation. Robot Comput Integr Manuf 17(5):421–427

Mohanty RP, Deshmukh SG (1998) Advanced manufacturing technology selection: a strategic model for learning and evaluation. Int J Prod Econ 55(3):295–307

Talluri S, Whiteside MM, Seipel SJ (2000) A nonparametric stochastic procedure for FMS evaluation. Eur J Oper Res 124(3):529–538

Talluri S, Yoon KP (2000) A cone-ratio DEA approach for AMT justification. Int J Prod Econ 66(2):119–129

Punniyamoorthy M, Ragavan PV (2003) A strategic decision model for the justification of technology selection. Int J Adv Manuf Technol 21(1):72–78

Chiadamrong N, O’Brien C (1999) Decision support tool for justifying alternative manufacturing and production control systems. Int J Prod Econ 60–61:177–186

Karsak EE (2002) Distance-based fuzzy MCDM approach for evaluating flexible manufacturing system alternatives. Int J Prod Res 40(13):3167–3181

Busby JS, Pitts CGC (1997) Real options in practice: an exploratory survey of how finance officers deal with flexibility in capital appraisal. Manage Account Res 8:169–186

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chan, F., Chan, H., Chan, M. et al. An integrated fuzzy approach for the selection of manufacturing technologies. Int J Adv Manuf Technol 27, 747–758 (2006). https://doi.org/10.1007/s00170-004-2246-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-004-2246-9