Abstract

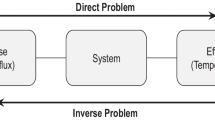

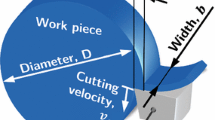

Heat fluxes on each cutting edge of a carbide double cutting drill are estimated during a high-speed machining process from temperature measurements in the drill tool and a direct model that has been established using the non integer system identification approach. A single experiment is required in order to characterize the transient thermal behavior of the tool. The non integer system identification method is based on the recursive linear least square algorithm. The inverse method is based on the constant function specification approach. Results obtained during machining lead to predict the tool wear and possible tool positioning defect.

Similar content being viewed by others

References

Herbert EG (1926) The measurement of cutting temperatures. Proc Inst Mech Eng 1:289–329

Shore H (1925) Thermoelectric measurement of cutting tool temperatures. J Washington Acad Sci 15:85–88

Stephenson DA (1993) Tool-work thermocouple temperature measurements: theory and implementation issues. J Eng Ind 115:432–437

Jaspers SP, Dautzenberg JH, Taminiau DA (1998) Temperature measurement in orthogonal metal cutting. Int J Adv Manuf Technol 14:7–12

Changeux (2001) Loi de comportement pour l’usinage. Localisation de la déformation et aspects microstructuraux. Thèse de Mécanique et Materiaux, Paris, no 2001-12, 159 pages

Kwon P, Schiemann T, Kountanya R (2001) An inverse estimation scheme to measure steady-state tool-chip interface temperatures using an infrared camera. Int J Mach Tools Manuf 41:1015–1030

Stephenson DA (1991) Assessment of steady-state metal cutting temperature models based on simultaneous infrared and thermocouple data. J Eng Ind 113:121–128

Stephenson DA (1991) An inverse method for investigating deformation zone temperatures in metal cutting. J Eng Ind 113:129–136

Stephenson DA, Ali A (1993) Tool temperatures in interrupted metal cutting. J Eng Ind 115:432–437

Laraqi N (1996) Phénomène de constriction thermique dans les contacts glissants. Int J Heat Mass Transf 39(17):3717–3724

Groover MP, Kane GE (1971) A continuing study in the determination of temperatures in metal cutting using remote thermocouples. J Eng Ind 93(2):603–608

Yen DW, Wright PK (1986) A remote temperature sensing technique for estimating the cutting interface temperature distribution. J Eng Ind 108:252–263

El-Wardany TI, Mohammed E, Elbestawi MA (1996) Cutting temperature of ceramic tools in high-speed machining of difficult-to-cut materials. Int J Mach Tools Manuf 36(5):611–634

Kim SW, Lee CM, Kim JS, Jung YH (2001) Evaluation of the thermal characteristics in high-speed ball-end milling. J Mater Process Technol 113:406–409

Lin J (1995) Inverse estimation of tool-work interface temperature in end mi lling. Int J Mach Tools Manuf 35(5):751–760

Elmoussami H, Battaglia J-L (2003) A method to estimate the average temperature on the cutting edge of tools. Application on the milling process. Int J of Experimental Heat Transfer 16(2):1–20

Battaglia JL, Elmoussami H, Puigsegur L (2002) Modélisation du comportement thermique d’un outil de fraisage; Approche par identification de système non entier. Comptes Rendus de l’Académi des Sciences, Mécanique 330:857–864

Battaglia JL, Le Lay L, Batsale JC, Oustaloup A, Cois O (2000) Heat flux estimation through inverted non integer identification models. Int J Therm Sci 39(3):374–389

Battaglia JL, Cois O, Puigsegur L, Oustaloup A (2000) Solving an inverse heat conduction problem using a non-integer identified model. Int J Heat Mass Transf 14(44):2671–2680

Battaglia JL, Puigsegur L, Kusiak A (2003) Représentation non entière du transfert de chaleur par diffusion: utilité pour la caractérisation et le contrôle non destructif thermique. Int J Therm Sci 75(4):350–370

Bourouga B, Briot J-M, Bardon J-P (2001) Influence de la vitesse et de la charge sur la conductance thermique de transport entre les bagues d’un roulement à rouleaux. Int J Therm Sci 40(7):622–637

Oldham KB, Spanier J (1974) The fractional calculus. Academic Press, New York London

Samko SG, Kilbas AA, Marichev OI (1993) Fractional Intervals and Derivatives. Theory and applications. Gordon and Breach, Amsterdam

Ljung L (1987) System identification: theory for the user. Prentice Hall

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Battaglia, JL., Kusiak, A. Estimation of heat fluxes during high-speed drilling. Int J Adv Manuf Technol 26, 750–758 (2005). https://doi.org/10.1007/s00170-003-2039-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-003-2039-6