Abstract

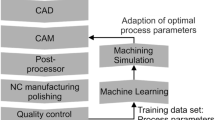

Besides the major factors such as the down force, back pressure and the rotating speed of wafer carrier, effect of polishing time is also an important issue in CMP processes. In this study, a neural-Taguchi method based on a cost-effective quasi time-optimisation technique for chemical-mechanical polishing (CMP) processes is developed. The key concept of this new technique is that an optimal process parameter set is obtained through a neural-network-simulated CMP process model. Under such an optimal parameter set, the desired material removal rate within-wafer-nonuniformity can be reached with the optimal polishing time. It has been proved by experiment that the proposed method can offer a better polishing performance while reducing the polishing time by 1/3.

Similar content being viewed by others

References

O’Mara WC (1994) Planarization by CMP: forecasting the future. Semicond Int July, pp 140–146

Semiconductor Industry Association (1994) The national technology roadmap for semiconductors. Semiconductor Industry Association, San Jose, CA

Steigerwald JM, Murarka SP, Gutmann RJ (1997) Chemical mechanical planarization of microelectronic materials. Wiley, New York

Tsai MS (1998) Short course for the integrated-circuit process. National Nano Device Lab., Taiwan

Chen LJ, Huang YL, Lin ZH, Chiou HW (1998) Pad thermal image endpointing for CMP process. CMP-MIC Conference, pp 28–35, 19–20 Feb 1998

Chan DA, Swedek B, Wiswesser A, Birang M (1998) Process control and monitoring with laser interferometry based endpoint detection in chemical mechancial planarization. IEEE/SEMI Advanced Semiconductor Manufacturing Conference, pp 377–384

Fang SJ, Barda A, Janecko T, Little W, Outley D, Hemple G, Joshi S, Morrison B, Shinn GB, Birang M (1998) Control of dielectric chemical mechancial polishing using an interferometry based endpoint sensor. Interconnect Technology Conference, pp 76–78

Wang GJ, Chen JL, Hwang JY (2001) A new optimization strategy for chemical mechanical polishing process. JSME Int J Series C 44(2):534–543

Tsai MY, Tsai JC, Liu C (1999) Mechanical wear models and experimental investigation for CMP process. Proceeding of the Sixth Symposium on Nano Device Technology, pp 20–23, Hsin-Chu, Taiwan

Wang GJ, Tsai JC, Tzeng PC (1998) Neural-Taguchi method for robust design analysis. J Chin Soc Mech Eng 19(2):223–230

Wang GJ, Wu JG, Chang K (2000) A new neural network based parameters optimization method. Proceeding of the Sixth International Conference on Automation Technology, Taipei, pp 609–616

Preston F (1927) The theory and design of plate glass polishing machines. J Soc Technol 11:214

Taguchi G, Wu YI (1979) Introduction to off-line quality control. Japan Qual Control Assoc, Nayoga, Japan

Ross P (1988) Taguchi techniques for quality engineering. McGraw-Hill, New York

Wang GJ, Chen JJ (2000) Cascade steepest descendant learning algorithm for multilayer feedforward neural network. JSME Int J C 43(2):350–358

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, GJ., Chou, MH. A neural-Taguchi-based quasi time-optimization control strategy for chemical-mechanical polishing processes. Int J Adv Manuf Technol 26, 759–765 (2005). https://doi.org/10.1007/s00170-003-1859-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-003-1859-8