Abstract

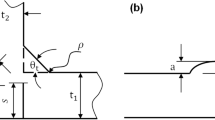

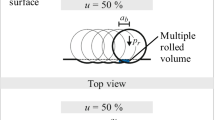

The external geometry of a fillet weld affects not only the quality but also the safety of a structure. Two parameters that influence the geometric quality of a fillet weld are the weld size and the weld surface profile. A 3D laser scanning measurement system integrating the techniques of reverse engineering is adopted in this study to provide a more accurate measurement of the weld profile. The section profiles of the external weld geometry along the longitudinal axis of the weld are generated by the measured data set through CAD software. A computer programme based on the AWS Structural Welding Code is used to judge the acceptability of a fillet weld based on the CAD section profile of the weld. The proposed 3D laser scanning system with integrated CAD software can provide a more accurate and efficient method to estimate the geometric quality of a fillet weld .

Similar content being viewed by others

References

Fessler H, Pappalettere C (1989) Plastic–elastic strains in two-dimensional sections of pa rtial-penetration fillet welds. J Strain Anal 24(1):15–21

Wu A, Ma XN, Murakawa H, Ueda Y (1996) Effects of welding procedures on residual stresses of T-joints. Trans JWRI 25(1):81–89

Spotts MF, Shoup TE (1998) Machine design, 7th edn. Prentice-Hall, Upper Saddle River, NJ, pp 373–414

Melior BG, Rainey RCT, Kirk NE (1999) Static strength of end and T fillet connections. Mater Des 20(4):193–205

Lee JI, Rhee S (2000) Prediction of process parameters for gas metal arc welding by multiple regression analysis. Proc Inst Mech Eng 214B:443–449

Bowman MD, Quinn BP (1995) Fillet weld profile measurement. Exp Tech (5):21–24

American Welding Society (1990) Structural Welding Code-Steel, 12th edn. AWS DI.I, Miami, FL

Lee KW (1999) Principles of CAD/CAM/CAE. Prentice-Hall, Upper Saddle River, NJ

Chen YH, Chen MS, Chien CK, Fan KC (1994) 3D CAD/CAM module system developed by microcomputers. In: Proceedings of the 11th national conference of the Chinese Society of Mechanical Engineers, Taichung, Taiwan, pp 281–289

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chang, CL., Chen, YH. Measurements of fillet weld by 3D laser scanning system. Int J Adv Manuf Technol 25, 466–470 (2005). https://doi.org/10.1007/s00170-003-1837-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-003-1837-1