Abstract

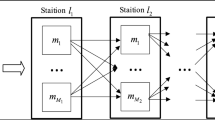

The flowline-based manufacturing system (FBMS) is a manufacturing environment wherein machines are arranged in the order in which jobs undergo operations, and jobs have an identical and uni-directional flow pattern. However, some or all jobs may not require processing on some machines. Scheduling of jobs in such a FBMS is considered in this paper with the focus on the development of non-permutation schedules. The significance of non-permutation schedules in improving the schedule performance measures, in the context of FBMS’s, is first brought out. A heuristic procedure to derive non-permutation schedules from a given permutation schedule is subsequently proposed. The minimization of total flowtime of jobs is considered as the objective in the first instance, followed by the consideration of the minimization of total weighted flowtime of jobs. An extensive computational experimentation has been performed to evaluate the effectiveness of the proposed heuristic in improving the performance measures. Further, the performance of the proposed heuristic in generating non-permutation schedules has been compared with that of the benchmark dispatching rules namely, the SPT and SWPT rules.

Similar content being viewed by others

Abbreviations

- n :

-

Total number of jobs available at time zero

- m :

-

Number of machines in the FBMS

- t (i, j):

-

Processing time of job i on machine j

- σ :

-

Set of jobs already scheduled, out of n jobs, at the given instant τ

- i :

-

Job to be scheduled

- ST (i, j):

-

Start time of job i on machine j

- FT (i, j):

-

Finish time of job i on machine j

- {S j}:

-

Job sequence on machine j. This defines the sequence in which jobs are processed on machine j.

- n j :

-

Number of jobs processed on machine j

- \(s^{j}_{k}\) :

-

Job processed in the k-th position of {S j} on machine j

- RST (k, j):

-

On machine j, start time of job i found in the k-th position of {S j} (i.e., start time of job \(s^{j}_{k}\) on machine j)

- RFT (k, j):

-

On machine j, finish time of job i found in the k-th position of {S j} (i.e., finish time of job \(s^{j}_{k}\) on machine j)

- CT i :

-

Completion time of the last operation of job i

- w i :

-

Weight (or relative importance or relative holding cost) for job i

- F σ :

-

Total flowtime of jobs in σ (i.e., sum of CT i ’s over all scheduled jobs)

- W σ :

-

Total weighted flowtime of jobs in σ (i.e., sum of (w i ×CT i )’s over all scheduled jobs)

- MS :

-

Makespan of the scheduled job set

References

Johnson SM (1954) Optimal two- and three-stage production schedules with setup times included. Nav Res Log Q 1:61–68

Campbell HG, Dudek RA, Smith ML (1970) A heuristic algorithm for the n-job, m-machines sequencing problem. Manage Sci 16B:630–637

Nawaz M, Enscore EE Jr, Ham I (1983) A heuristic algorithm for the m-machine, n-job flowshop sequencing problem. OMEGA 11:91–95

Widmer M, Hertz A (1989) A new heuristic method for the flowshop sequencing problems. Eur J Oper Res 41:186–193

Taillard E (1990) Some efficient heuristic methods for the flowshop sequencing problem. Eur J Oper Res 17:65–79

Ogbu FA, Smith DK (1990) The application of the simulated annealing algorithm to the solution of the n/m/Cmax flowshop problem. Comput Oper Res 17:243–253

Ishibuchi H, Misaki S, Tanaka H (1995) Modified simulated annealing algorithm for the flowshop sequencing problem. Eur J Oper Res 81:388–398

Ben Daya M, Al-Fawzan (1998) A tabu search approach for the flowshop scheduling problem. Eur J Oper Res 109:88–95

Miyazaki S, Nishiyama N, Hashimoto F (1978) An adjacent pair-wise interchange approach to the mean flowtime scheduling problem. J Oper Res Soc Japan 21:287–299

Rajendran C, Chaudhuri D (1992) An efficient heuristic approach to the scheduling of jobs in a flowshop. Eur J Oper Res 61:318–325

Rajendran C (1993) Heuristic algorithm for scheduling in a flowshop to minimize total flowtime. Int J Prod Econ 29:65–73

Ho JC (1995) Flowshop sequencing with mean flowtime objective. Eur J Oper Res 81:571–578

Rajendran C (1994) A heuristic for scheduling in flowshop and flowline-based manufacturing cell with multi-criteria. Int J Prod Res 32:2541–2558

Gelders LF, Sambandam N (1978) Four simple heuristics for scheduling a flowshop. Int J Prod Res 16:21–238

Miyazaki S, Nishiyama N (1980) Analysis for minimizing weighted mean flowtime in flowshop scheduling. J Oper Res Soc Japan 23:118–132

Rajendran C, Ziegler H (1997) An efficient heuristic for scheduling in a flowshop to minimize total weighted flowtime. Eur J Oper Res 103:129–138

Pinedo M (1995) Scheduling: theory, algorithms and systems. Prentice Hall, Englewood Cliffs

Dannenbring DG (1977) An evaluation of flowshop sequencing heuristics. Manage Sci 23:1174–1182

Blackstone JH, Phillips DT, Hogg GL (1982) A state-of-the-art survey of dispatching rules for manufacturing jobshop operations. Int J Prod Res 20:27–45

Giffler B, Thomson GL (1960) Algorithms for solving production scheduling problems. Oper Res 8:487–503

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pugazhendhi, S., Thiagarajan, S., Rajendran, C. et al. Relative performance evaluation of permutation and non-permutation schedules in flowline-based manufacturing systems with flowtime objective. Int J Adv Manuf Technol 23, 820–830 (2004). https://doi.org/10.1007/s00170-003-1661-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-003-1661-7