Abstract

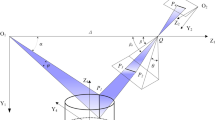

Coordinate measuring machines (CMMs) are widely used in the gear manufacturing industry. One of the main issues for contact inspection using a CMM is the sampling technique. In this paper the gear tooth surfaces are expressed by series of parameters and inspection error compensation and initial value optimisation method are presented. The minimum number of measurement points for 3D tooth surfaces are derived. If high precision is required, more points need to be inspected. The sampling size optimisation is obtained from the criterion equation. The surface form deviation and initial values are optimised using the minimum zone method and genetic algorithms. A feature-based inspection system for spur/helical gears is developed and trials and simulations demonstrate that the method developed is suitable and very effective.

Similar content being viewed by others

References

Assessment of position, size and departure from nominal form of geometric features. British Standards Institution, BS 7172.

Hurt JJ (1980) A comparison of several plane fit algorithms. Ann CIRP 29:381-384

Weckenmann A, Heinrichowski M, Mordhorst HJ (1991) Design of gauges and multipoint measuring system using co-ordinate measuring machine data and computer simulation. Precision Eng 13:203-207

Yau H, Menq C (1992) An automated dimensional inspection environment for manufactured parts using co-ordinate measuring machines. Int J Prod Res 30(7):1517-1536

Lotze W, Haertig F (2001) 3D gear measurement by CMM. Proceedings of Laser Metrology and Machine Performance, Birmingham, UK, pp333-344

LK gear inspection software, http://www.lk-cmm.com/gear.html

Cheng K, Gao CH, Harrison DK (2000) 3D surface profile deviation evaluation based on CMM measured data, Proceedings of the 16th International Conference on Computer Aided Production Engineering , Edinburgh, UK, 7-9 Aug, pp503-510

Gao CH, Cheng K, Webb D (2001) An investigation to surface features inspection on complex shaped components. In: CD-ROM Proceedings of the IFIP Conference on Feature Modeling and Advanced Design-For-The-Life-Cycle Systems, Valenciennes, France, 12-14 June

Litvin F (1994) Gear Geometry and Applied Theory. PTR Prentice Hall, NJ

James G et al. (1996) Modern Engineering Mathematics, 2nd edn. Addison Wesley Longman, Boston

Pattison RL, Andrews JD (1999) Genetic algorithms in optimal safety system design. Proc Inst Mech Eng 213(E):187-197

Goldberg DE (1989) Genetic Algorithms in Search, Optimisation, and Machine Learning. Addison Wesley Longman, Boston

Huang J (1999) An exact minimum zone solution for three dimensional straightness evaluation problems. Precision Eng 23:204-208

Fukuda M, Shimokohvbe A (1984) Algorithms for form error evaluation-methods of the minimum zone and the least squares. Proceedings of the International Symposium on Metrology for Quality Control on Production, Tokyo, Japan, pp197-202

Xiong YL (1990) Computer aided measurement of profile error of complex surfaces and curves: theory and algorithm. Int J Mach Tools Manuf 30(3):339-357

Cochran WG (1953) Sampling techniques, 2nd edn. Hohn Wiley, NY

Rabiner LR, Gold B (1975) Theory and Application of Signal Processing. Prentice Hall, NY

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gao, C., Cheng, K. & Webb, D. Investigation on sampling size optimisation in gear tooth surface measurement using a CMM. AMT 24, 599–606 (2004). https://doi.org/10.1007/s00170-003-1595-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-003-1595-0