Abstract

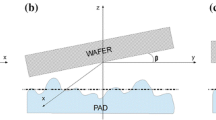

In this paper, relative velocity at a given point on the wafer was first derived. The revolutions of wafer and pad are assumed the same and the axisymmetric uniformly distributed pressure form is given. Thus, a 2D axisymmetric quasic-static model for chemical-mechanical polishing process (CMP) was established. Based on the principle of minimum total potential energy and axisymmetric elastic stress-strain relations, a 2D axisymmetric quasic-static finite element model for CMP was thus established. In this model, the four-layer structures including wafer carrier, carrier film, wafer and pad are involved. The von Mises stress distributions on the wafer surface were analysed, the effects of axial, hoop, radial and shear stresses to von Mises stress and the effects of axial, hoop, radial and shear strains to deformation of the wafer were investigated. The findings indicate that near the wafer centre, von Mises stress distribution on the wafer surface was almost uniform, then increased gradually with a small amount. However, near the wafer edge, it would decrease in a large range. Finally, it would increase dramatically and peak significantly at the edge. Besides, the axial stress and strain are the dominant factors to the von Mises stress distributions on the wafer surface and the wafer deformation, respectively.

Similar content being viewed by others

References

Runnels SR, Renteln P (1993) Modeling the effect of polish pad deformation on wafer surface stress distributions during chemical-mechanical polishing. Dielectric Sci Technol 6:110–121

S. R. Runnels SR, Eyman LM (1994)Tribology analysis of chemical-mechanical polishing. J Electrochem Soc 141(6):1698–1701

Kaanta CW, Landis HS (1991) Radial uniformity control of semiconductor wafer polishing. US Patent 5,036,630, 1991

Wang D, Lee J, Holland K, Bibby T, Beaudoin S, Cale T (1997) Von Mises stress in chemical-mechanical polishing processes. J Electrochem Soc 144(3):1122–1127

Srinivasa-Murthy C, Wang D, Beaudoin SP, Bibby T, Holland K, Cale TS (1997) Stress distribution in chemical-mechanical polishing. Thin Sol Film 308:533–537

Baker AR (1997) The origin of the edge effects in CMP. In: Proceedings of the Electrochemical Society 96(22):228–237

Yu TK (1995) Modeling of the chemical-mechanical polishing process. In: Proceedings of the Materials Research Society, ULSI-X Conferences, pp 187–194

Tseng WT (1998) Machine-related wafer pressure distribution and its influence on chemical-mechanical polishing process. In: The Electrochemical Society Proceedings, pp 457

Castillo-Mejia D, Perlov A, Beaudoin S (2000) Qualitative prediction of SiO2 removal rates during chemical mechanical polishing. J Electrochem Soc 147(12):4671–4675

Ahmadi G, Xia X (2001) A model for mechanical wear and abrasive particle adhesion during the chemical-mechanical polishing process. J Electrochem Soc 148(3):G99–G109

Yu TK, Yu CC, Orlowski M (1993) A statistical polishing pad model for chemical-mechanical polishing. IEDM Tech Dig pp 865–868

Rao SS (1989) The finite element method in engineering. Pergamon, New York

Acknowledgements

It is gratefully acknowledged that the National Science Council of the Republic of China provided funds (Grant No.: NSC 90-2212-E-237-001) for the financial support of this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lin, YY., Lo, SP. A study of a finite element model for the chemical mechanical polishing process. Int J Adv Manuf Technol 23, 644–650 (2004). https://doi.org/10.1007/s00170-002-1469-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-002-1469-x