Abstract

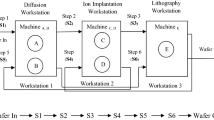

The semiconductor manufacturing industry is one of the most important industries in Taiwan. Wafer fabrication is an essential process in semiconductor manufacturing. However, controlling the production system on the shop floor is extremely difficult owing to the complicated manufacturing process and reentrant characteristics. In this paper, the shop floor control (SFC) integration strategies (order review/release, dispatching, and rework strategies) in wafer fabrication are considered with using several performances. We reviewed the literature on SFC strategies in wafer fabrication. The proposed combination simulation and simulated annealing (SA) algorithm is presented for SFC strategies in wafer fabrication. The objective was to seek the near global optimum solution for the combination of SFC strategies for a specific performance indicator. From the results, the proposed methodology was found to perform well for combinations of SFC strategies using different performance indicators in wafer fabrication. However, no single combination of SFC strategies could satisfy all performance indicators. Hence, considering the trade-off among these production control strategies, a suitable strategy should be chosen based on the system control tactics. Considerable computational time was saved in this research.

Similar content being viewed by others

References

Uzsoy R, Lee CY, Martin-Vega LA (1992) A review of production planning and scheduling models in the semiconductor industry Part I: System characteristics, performance evaluation and production planning. IIE Trans 24(4):47–60

Uzsoy R, Lee CY, Martin-Vega LA (1994) A review of production planning and scheduling models in the semiconductor industry Part II: Shop-floor control. IIE Trans 6(5):47–60

Melynk SA, Ragatz GL (1988) An evaluation of order release mechanisms in a job-shop environment. Decis Sci 19(1):167–189

Glassey CR, Resende MGC (1988) A scheduling rule for job release in semiconductor fabrication. Oper Res Lett 7(5):213–217

Wein LM (1988) Scheduling semiconductor wafer fabrication. IEEE Trans Semicond Manuf 1(3):115–128

Miller DJ (1990) Simulation of a semiconductor manufacturing line. Commun ACM 33(10):99–108

Lou SXC, Kager PW (1989) A robust production control policy for VLSI wafer fabrication. IEEE Trans Semicond Manuf 2(4):159–164

Spearman ML, Woodruff DL, Hopp WJ (1990) CONWIP: A pull alternative to kanban. Int J Prod Res 28(5):879–894

Lee CE, Chen CW (1997) A dispatching scheme involving move control and weighted due date for wafer foundries. IEEE Trans Compon, Pack, and Manuf Technol C 20(4):268–277

Glassey CR, Resende MGC (1988) Closed-loop job release control for vlsi circuit manufacturing. IEEE Trans Semicond Manuf 1(1):36–46

Kim YD, Kim JU, Lim SK, Jun HB (1998) Due-date based scheduling and control policies in a multiproduct semiconductor wafer fabrication facility. IEEE Trans Semicond Manuf 11(1):155–164

Sha DY, Hsieh LF,Chen KJ (2001) Wafer rework strategies at the photolithography stage. Int J Ind Eng 8(2):122–130

Zarger A (1995) Effect of rework strategies on cycle time. 17th International Conference on Computers and Industrial Engineering 29(1–4):239–243

Lu SCH, Ramaswamy D,Kumar PR (1994) Efficient scheduling policies to reduce mean and variance of cycle-time in semiconductor manufacturing plants IEEE Trans Semicond Manuf 7(3):374–388

Fowler JW, Brown S, Gold H,Schoemig A (1997) Measurable improvements in cycle-time-constrained capacity. IEEE International Symposium on Semiconductor Manufacturing Conference Proceedings pp. A21–A24

Hsieh BW, Chen CH,Chang SC (1999) Fast fab scheduling rule selection by ordinal comparison-based simulation. IEEE International Symposium on Semiconductor Manufacturing Conference Proceedings, pp. 53–56

Chung SH,Huang HW (1999) The design of production activity control policy. J Chin Inst Ind Eng 16(1):93–113

Kim J, Leachman RC,Suh B (1996) Dynamic release control policy for the semiconductor wafer fabrication lines. J Operat Res Soc 47(12):1516–1525

Kim YD, Lee DH, Kim JU,Roh HK (1998) A simulation study on lot release control, mask scheduling, and batch scheduling in semiconductor wafer fabrication facilities. J Manuf Syst 17(2):107–117

Sha DY, Hsieh LF,Lin SH (2001) A study on wafer rework strategies and dispatching rules at the photolithography stage. ProdInventory Manage J (Rev)

Metropolis N, Rosenbluth A, Rosenbluth M,Teller A (1953) Equation of state calculation by fast computing machines. J Chem Phys 21:1087–1092

Kirkpatrick S, Gelatt CD Jr.,Vecchi MP (1983) Optimization by simulated annealing. Science 220:671–680

Chang HH (1999) Optimal parameter design via soft computing. Dissertation, National Chao Tung University

Ponnambalam SG, Jawahar N,Aravindan P (1999) A simulated annealing for job shop scheduling. Prod Plann Control 10(8):767–777

Beragamaschi D, Cigolini R, Perona M,Portioli A (1997) Order review and release strategies in a job shop environment: A review and a classification. Int J Prod Res 35(2):399–420

Blackstone JH, Phillips DT, Hogg GL (1982) A state-of-the-art survey of dispatching rules for manufacturing job shop operations. Int J Prod Res 20(1):27–45

Yan H, Lou S, Sethi S, Gardel A,Deosthail P (1996) Testing the robustness of two-boundary control policies in semiconductor manufacturing. IEEE Trans Semicond Manuf 9(2):285–288

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sha, D.Y., Liu, CY. A simulated annealing algorithm for integration of shop floor control strategies in semiconductor wafer fabrication. Int J Adv Manuf Technol 22, 75–88 (2003). https://doi.org/10.1007/s00170-002-1444-6

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-002-1444-6