Abstract

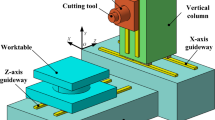

This paper proposes a modified volumetric error model that includes spindle error motions as well as geometric errors. The model is constructed using rigid-body kinematics and homogeneous transformation matrices and an additional error matrix describing spindle error motions is included. The suggested model predicts the positioning errors at a given axis position as a function of both the axis position and the engaged spindle rotation angle. Two circular interpolation tests (inner and outer circle of the same radius) are simulated and the machined part profiles are predicted. To verify the simulation results, machining tests are performed according to the ISO 10791-7 standard. The error model with spindle errors shows a better agreement, between the simulated and measured roundness errors, than the simple geometric model. It can be seen that the geometric errors determine the basic part profiles and the spindle errors change the basic profiles according to the magnitude of the errors and the spindle rotation angle.

Similar content being viewed by others

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Choi, JP., Lee, SJ. & Kwon, HD. Roundness Error Prediction with a Volumetric Error Model Including Spindle Error Motions of a Machine Tool . Int. Journ. Adv. Manufac. Tech. 21, 923–928 (2003). https://doi.org/10.1007/s00170-002-1407-y

Issue Date:

DOI: https://doi.org/10.1007/s00170-002-1407-y