Abstract

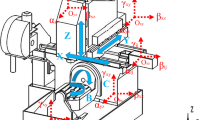

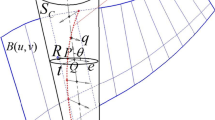

When a 3-axis CNC machining centre is used for producing an impeller, great difficulties, i.e. collisions between the cutting tool and the impeller, can occur. The blade of an impeller is usually designed with a ruled surface. As the surface is normally twisted in design to achieve the required performance, it can cause overcut and collision problems during machining. The hub of the impeller is usually designed with an irregular surface, and is machined within a narrow and deep groove. The issues – how to satisfy the quality requirements of the part, reduce the machining time, and avoid the occurrence of collision – become an integral problem. This work develops an integrated 5-axis machining module for a centrifugal impeller by combining related machining technologies. As a result, cutter location (CL) data based on the geometric model of blade and hub are generated. Finally, the CL data are confirmed through software simulation. The results of verification show that the machining methodology and procedure adopted are successful.

Similar content being viewed by others

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Young, HT., Chuang, LC. An Integrated Machining Approach for a Centrifugal Impeller . Int. Journ. Adv. Manufac. Tech. 21, 556–563 (2003). https://doi.org/10.1007/s00170-002-1382-3

Issue Date:

DOI: https://doi.org/10.1007/s00170-002-1382-3